Building the future with geopolymer concrete – new markets, new products, a clear vision

The construction of a new mixing plant has opened a new chapter for Kortmann Beton GmbH & Co. KG in its 75th year of existence. The company consistently focuses on sustainable innovation – in particular, on geopolymer concrete. This concrete is completely cement-free and significantly reduces the ecological footprint compared to conventional concrete.

Since its foundation in 1950, Kortmann Beton has stood for innovation, reliability, and technological progress in the concrete industry. What once began with a used truck owned by Carl Eduard Kortmann in Schüttorf, in the German state of Lower Saxony, evolved in the course of more than three generations into a leading concrete plant with nationwide appeal.

As early as in the 1960s, the company entered the building materials trade with a focus on gravel, cement, and later paving blocks. In 1971, the founder’s son Karl – young, courageous, and full of ideas – took over the company. In 1975, the company bought its first concrete plant in nearby Gronau, marking the start of its own stone production. Just a few years later, the current plant was built at Holmers Kamp in Schüttorf.

In the 1990s, the company achieved a breakthrough in the market with its proprietary “TASIKO®-System”, an innovative modular system for liquid-tight surfaces. This set new standards and made Kortmann Beton known beyond the region.

With the arrival of Henning and Matthias Kortmann, the third generation, supported by managing director Julian Krümpel, a new era began in 2010: digitalization, e-mobility, and sustainability became the focus. In 2024, Kortmann Beton was awarded the Innovation Prize for its “geopolymer concrete.” In 2025, the company celebrates its 75th anniversary – with the clear goal of continuing to revolutionize the industry.

Managing Director Julian Krümpel on the company‘s vision: ”’We are revolutionizing concrete‘ – this mission has accompanied us for 75 years. Kortmann Beton stands for technological leadership in charging infrastructure, sustainable solutions for environmental and resource protection, and innovative products that simplify, accelerate, and make construction processes safer. Today, we are working with over 150 employees on new solutions for a connected, climate-friendly, and high-performance infrastructure.“

Product areas

Collision protection:

Kortmann’s collision protection systems reliably protect sensitive facilities and infrastructures from vehicle impact – even from the highest impact loads. This not only secures equipment, but also investments.

Design & function:

Kortmann Beton offers thought-through programs for garden and landscaping as well as infrastructure:

Design pavement & patio slabs. Aesthetically demanding and robust

Industrial pavement & curbstone systems: for heavy loads and industrial areas

Signal block:

developed especially for road shoulder stabilization – dimensionally stable, functional and durable.

Energy infrastructure:

For meeting the challenges of the energy transition, Kortmann Beton delivers tailor-made solutions:

Compact stations

Foundations for substations, light poles and switch cabinets

Cable ducts, manhole covers and custom-made solutions.

The precast elements ensure fast, secure and precise installation and are in use throughout Europe.

E-mobility & heat pumps:

Kortmann promotes sustainable mobility and energy supply – with precast concrete foundations for:

Charging stations (AC & DC)

Charging parks and

Heat pump systems.

These solutions enable short construction times, maximum stability and minimal interfaces at the construction site.

Environmental protection – the Tasiko system

The Tasiko modular system is the response to the requirements of the German WHG and AwSV installations:

Precast concrete elements approved by the building authorities

Liquid-tight execution for meeting the requirements of German LAU and HBV systems

High concrete quality, shorter construction time, exchangeable element.

Tasiko stands for tested safety, environmental compatibility and economy – an ideal solution for industry, waste disposal and energy supply.

Building the future with geopolymer concrete

The construction of a new mixer plant opened a new chapter. Kortmann not only taps into new markets, but also continuously focuses on sustainable innovation – most of all geopolymer concrete, which not only contains no cement, but is also free of CO₂ and reduces the ecological footprint by up to 75 %, compared to conventional concrete.

1. One step ahead of energy infrastructure

Kortmann strengthens its role as system supplier for an advanced energy infrastructure and will in future emphasize its support the extension of charging and solar parks. The solutions at a glance:

Foundations for charging stations

Roof foundation for solar systems

Transformer stations for charging parks and the energy transition

Cable ducts, transformer routes and collision protection systems.

Thus, a complete package for all applications for charging and energy centers is offered – modular, efficient and futureproof.

2. Entry into building construction: CO₂-free façade

blocks

Kortmann is entering the building construction sector and is developing its own propriety product line for façade blocks of geopolymer concrete. This innovative solution combines:

CO₂-free production

High architectural design freedom

Excellent sound and thermal insulation properties.

The aim: rethinking architectural concrete – for a future-oriented architecture, which is not only well-designed, but climate-positive as well.

3. Garden and landscape construction: extension of

the product range

Kortmann is consistently expanding its offering also for the design and construction of gardens:

Garden wall systems

Concrete block steps.

These products are not only functional, but also versatile in design – perfect for modern outdoor facilities in the private and public space.

Modernization of plant technology

New construction of the mixing plant

Following two years of intensive planning and additional two years of construction, it is now reality: the new mixing plant at Kortmann Beton – a technical powerhouse that sets new standards in concrete production. After a commissioning phase of three months, utilization is taking place step by step.

Smooth transition – production continued under full load:

Despite the structural and technical challenges, the entire newbuild could be realize during ongoing production. Initially, precast element production was supplied with concrete from the new mixing plant; next followed the connection to automatic production.

The 40-year old concrete mixing tower had continued operation during the entire construction phase – supplied by the existing silo that continued to be reliably supplied with aggregates. Particularly demanding: the new mixing plant was built entirely around the existing conveyor belt. This detail had represented a special challenge already in the planning phase.

Transition from the old to the new mixing plant took place in a tightly-timed time window of only 14 days. During this time, all systems were connected, transition points inspected and processes re-aligned. Immediately afterwards, the old mixing plant was completely dismantled – including removal of the conveyor belt from the new structure.

The belt system had been supplied by VHV Anlagenbau, the control system has been taken over by Bikotronic. All aggregates, colors and binding agents can be flexibly allocated to each mixer – this makes for maximum product variety with maximum efficiency.

At a total height of 36 m (including antenna: 48 m) the mixer extends beyond the plant at Holmers Kamp and symbolizes progress and sustainability.

Technology and performance

The new mixing plant combines state-of-the-art components and maximum flexibility:

Core concrete mixer (Haarup): 1 × 2.5 m³ and 2 × 2.0 m³

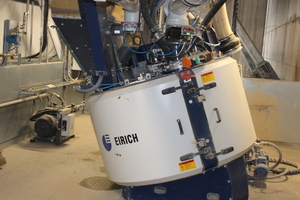

Face concrete mixer (Eirich): 2 × 0.33 m³

Aggregate silos: 43 with 7,500 tons of storage capacity each

Binder storage: 1,300 tons for 11 different products

Admixtures: space for 8 different products

Color batcher (Würschum): 10 brilliant colors, including separate lines for white and black – all colors can be used with every mixer

Feeding capacity: up to 340 tons per hour.

New heart for mechanical production & precast elements

With this new mixing plant, precast element production is optimized in a targeted manner – thanks to he fast mixing times, production can be excellently adapted.

The connected paver block machine from manufacturer Hess, on which a total of 7,000 Wasa Uniplast Ultra production boards have been in use since 2018, has been supplemented with a mold change system – designed to fully utilize the capacity of the new mixing plant. On the block machine, products for the Tasiko system as well as the design and functional paving are manufactured and, in future, the new façade blocks.

Focus on sustainability

In addition to performance, ecology has been a key focus from the beginning. This included:

Significant cement savings

More efficient use of electricity and

The use of geopolymer concrete to reduce CO₂ emissions.

The new mixing plant thus directly contributes to Kortmann‘s goal of achieving the industry’s most sustainable concrete production. The mixing plant at Kortmann Beton was not only designed to meet current needs, but was also developed with a view to future requirements – including the option of a rail connection for sustainable raw materials delivery. This means more capacity, more efficiency, and more environmental awareness.

Automation at the highest level: Thanks to state-of-the-art technology, only two employees are needed to control both the mixing plant and block production during normal operation. The mixers used have an integrated self-cleaning system, which significantly shortens the cleaning process and minimizes downtime.

Production advantages across the board: the new plant not only increases production efficiency, but also quality and cost-effectiveness:

Increased efficiency in precast element production through optimized concrete availability and shorter cycle times

Higher color intensity in decorative paving blocks, which significantly improves surface quality and durability

Flexible aggregate, color, and binder control for maximum product variety and response speed.

Conclusion: With its new mixing plant, Kortmann Beton is sending a strong signal for automation, resource conservation, and intelligent production processes – and thus for laying the foundation for further growth in the areas of precast elements, decorative paving, and sustainable concrete technology.

Block machine from Hess

With the block machine from Hess, serial production of paving blocks and design elements at Kortmann Beton attains a new level of quality and efficiency. The combination of automatic mold changer, intelligent reject control and efficient logistics ensures maximum process reliability with minimum personnel requirements:

The automatic mold changer enables extremely short changeover times – without manual intervention

A robot sorts rejects fully automatically directly on the line

Thanks to the precise control of the new mixing system, rejects have been reduced to just 1% – an outstanding figure in an industry comparison

Thanks to their homogeneous, glass fiber-reinforced solid plastic material, Wasa Uniplast Ultra production boards ensure that stone products maintain their high quality even after many years of use

The integrated pallet magazine offers space for up to 350 pallets

A well-thought-out destacking system ensures the automated transfer of finished products to shipping pallets.

Strong partnership for flagship projects

What began with a recommendation, quickly became a flagship project: a mechanical engineering company for the concrete industry in Spelle, Germany, drew Kortmann Beton GmbH & Co. KG‘s attention to Wissing Kreativ Bau GmbH – and thus to a project with a signal effect: Europe‘s largest mixing and batching plant in Schüttorf. After the initial meeting between Michael Wissing (Managing Director at Wissing Kreativ Bau GmbH) and Kortmann Managing Director Julian Krümpel, it was clear: here, two entrepreneurs are meeting who share the same values and approach to work – solution-oriented, down-to-earth, and forward-looking.

Michael Wissing comments: „After an intensive planning and tendering phase, we were awarded the contract for civil engineering, building construction, and structural engineering – and just eight weeks later, the first machines rolled in. What followed was a tour de force of architectural engineering: working in shifts, our teams erected a concrete structure over 45 meters high in just 16 months – precisely planned, logistically challenging, and structurally extraordinary. The project was much more than a structural masterpiece – it marked the beginning of a partnership built on trust, supported by short coordination processes, joint solutions, and a cooperative relationship between equals.“

The collaboration between Wissing and Kortmann continued to develop rapidly: today, complex projects are being realized throughout Germany: highly specialized filling plants for mineral oil companies, substations for network providers as well as infrastructure for energy supply of the future. Wissing is responsible for the construction, while Kortmann supplies the appropriate precast concrete elements. This collaboration results in high-quality projects throughout Germany.

One remarkable aspect: many of the precast elements supplied were manufactured with the very same mixing plant that was once jointly built. This is a successful example of circular economy in action – well thought-out and efficient from planning to completion.

In conclusion, Managing Director Julian Krümpel summarized: „Our claim remains clear: we are building the future – sustainable, innovative and holistically. With the new mixing plant, our geopolymer technology, and an expanded product range, we are shaping the infrastructure of tomorrow – intelligently, efficiently, and environmentally consciously. Incidentally, the new mixing plant is more than just a construction project – it is a commitment to innovation, quality, and sustainability. It makes Kortmann Beton fit for the coming decades and sends a clear signal: We are revolutionizing concrete!“

CONTACT

Kortmann Beton GmbH & Co.KG

Holmers Kamp 6

48465 Schüttorf/Germany

+49 5923 9663-0