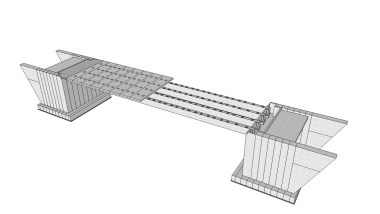

Building faster with precast – New rules and standards for federal highways

Germany has a high-performance infrastructure. Maintaining, renewing and expanding it in line with demand is one of the most important tasks to be solved in order to retain the attractiveness of Germany as a place to do business in the long run. However, the high impact on bridges, in particular, has left clear traces over the past few decades. Increased efforts must be made to upgrade these structures for the future. For this purpose, they must be re-verified structurally and, if necessary, strengthened, modernized or replaced with efficient new structures in accordance with economic considerations. Policy makers have responded to these requirements by putting an even stronger focus on the maintenance of transport infrastructure, with a particular emphasis on structures, as stipulated in the agreement of the governing coalition with regard to federal highways.

In order for investments in transport routes to have a quick and efficient effect, all planning activities, procedures and coordination efforts must be accelerated and simplified as much as possible. End-to-end digitalization at all levels is an important prerequisite for this. Likewise, the typification and standardization of structures as well as innovative contract award procedures should contribute to accelerating construction turnover. In other words, these are good preconditions for using precast elements.

Thanks to their serial prefabrication, precast elements can shorten

the construction process, which, in turn, reduces traffic-related carbon emissions because congestion-prone phases in the traffic flow are eliminated by speeding up construction. Thus, prefabricated elements of any type can have a positive influence on sustainability in road construction.

Even though precast solutions are not suitable for every project, the Federal Ministry for Digital and Transport has updated regulations for the design and construction of precast elements and extended the range of applications to promote this construction method. Thus, it will be possible to work with concrete grades up to C80/95 or to design precast components for the specific loads they will be exposed to. Even from today’s perspective, the precast industry is thus in a good position to contribute actively to ensuring the long-term performance of our road infrastructure.