South Korea: power of innovation at DecoPave

DecoPave Co. Ltd. Is a South Korean concrete elements producer, specialized in developing, manufacturing and selling a large variety of concrete blocks and pavers. Eng. Park, CEO of company DecoPave Co. Ltd. deliberately opted for the know-how from MCT Italy and focused on quality when selecting the batch plant and main components.

DecoPave Co. Ltd. Is a South Korean concrete elements producer, specialized in developing, manufacturing and selling a large variety of concrete blocks and pavers.

The company, founded in October 2012 by the innovative CEO, Eng. Park Moon-Soek, has the corporate philosophy of becoming a specialist in urban water management, providing top-quality blocks with differentiated water permeability and skid-proof feature, eco-friendly concrete products acting as air-purification elements from pollution.

To ensure superior quality, DecoPave has acquired technical and safety certifications from related institutions and inspection authorities.

Aqua Core Block

Aqua Core Block, one of DecoPave’s innovative product, is an eco-friendly water-permeable block developed to solve downtown flooding mainly caused by torrential downpours and heavy monsoon rains.

The great permeability of the entire structure of the block provides excellent drainage capability, which can store rainwater temporarily within a short time, and it helps to prevent pools of rainwater and road inundation by effectively absorbing and dispersing the rainwater. The Aqua Core Block has improved the problem of being clogged of traditional blocks about six months after installation. In addition, its rainwater storage function contributes to the growth of nearby plants thus minimizing the urban “heat island” effect.

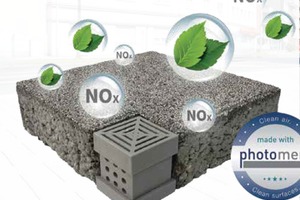

Air Care Block

Air Care patented solution is an air-purifying permeable block with self-cleaning properties. In particular, the air purification block of DecoPave attracts the attention as a next-generation block as it boosts the effect of effectively removing organic substances such as nitrogen oxides (NOx), sulfur oxides, and formaldehyde from the atmosphere through a photocatalytic reaction that reacts with light energy, unlike general sidewalk blocks.

In addition, in order to compensate for the rapid decline in efficiency due to wear, which was pointed out as a problem with photocatalytic technology, fly ash with pozzolanic properties was added to increase long-term strength by more than 20%, and to prevent whitening and to secure color stability. It also has a “Self Cleaning” feature in which organic and non-organic contaminants such as fine dust, drinks, etc. are easily removed by rainwater due to high hydrophilic property.

4th Industrial Revolution

In the era of the 4th Industrial Revolution deeply affected by the Corona 19 Crisis, DecoPave Co., Ltd. invested in a fully new automated factory, located in Danyang. The smart factory is one of the largest in East Asia with a 100% automated system for the entire process: from aggregates and raw materials loading and dosing, going through concrete production and packaging of finished products.

The ambitious Eng. Park, CEO of company DecoPave Co. Ltd. deliberately opted for the know-how from MCT Italy and focused on quality when selecting the batch plant and main components. In particular the batch plant is equipped with many innovative features that are essential for the production of concrete products with a high-quality and colored facing concrete layer.

Eng. Park Moon-Seok is taking a leap once again, breaking through the corona 19 crisis with the production of Air Care Block and Aqua Core Block. These blocks are the flagship products of the new Smart Factory.

DecoPave Co. Ltd. 3rd factory was completed in June with successfully trials and it is equipped with a 100% automation system for the entire process: it is possible to operate the full factory with only two operators sitting in the joint control room for the entire equipment: MCT Italy‘s batch plant, Rotho‘s curing room, MASA‘s press machine.

MCT Italy: best technical solution & layout

DecoPave Co. Ltd. management during the evaluation of the new investment, thanks to its knowledge and experience in the production of blocks & pavers, has analyzed some European suppliers and decided to proceed with MCT Italy, in a strong collaboration with the local partner Hanin.

After a long series of visits of MCT Italy and DecoPave Co. Ltd. representatives at several production facilities already running in USA, MCT Italy technical department was able to develop and propose a fully customized solution which impressed the customer for speed, redundancy and precision in the dosing of the components.

A team of MCT key persons were appointed to the project in order to develop in a true partnership with the customer the complete process of pre-installation, erection and commissioning.

One of the most appreciated aspects from DecoPave Co. Ltd. is the complete pre-installation of the plant performed at the MCT Italy Head Quarter, where customer‘s technical team carried out the dry test and started to get comfortable with the new equipment.

Massive Plant for most accurate dosing precision

The automatic aggregate loading system, starting from the primary receiving hopper, has been studied in order to avoid any kind of contamination among the different colored aggregates.

The several conveyor belts are equipped with electrical scrapers actuated only when colored materials are loaded; furthermore, every conveyor has an automatic washing system which guarantees the cleanest environmental.

The batching plant, carefully engineered with DecoPave Co. Ltd. engineers in every steps, has an aggregates storage of huge capacity:

1.200 cubic meters (1.900 ton) total aggregates storage, divided into 13 compartments

660 cubic meters into 9 compartments for base mix (grey concrete);

540 cubic meters for face mix (colored concrete);

2 mobile hoppers to contain and stock special aggregates of 2 cubic meters;

Two aggregates scales are able to feed, in an extreme fast way the two mixers:

1 Planetary Mixer for base mix (grey concrete) type 3000\2000 with compacted concrete of 2m3

1 Planetary intensive Mixer for face mix (colored concrete) type 750\500 with compacted concrete of 0,5 m3.

A large selection of colors can be added to the concrete through automatic dosing system: 6 different granulate colors and 2 different powder colors.

Underneath both mixer, MCT Italy installed 2 Betonmix that discharge the right color from the right bucket into the press with 2 conveyor belts.

The total flexibility of the color blending is ensured by the weighing systems of the single hoppers and by the metered extraction belts located on every hopper. The shuttling of the whole Betonmix in its rails, then, makes all color blending possible, achieving the consistency or the IN-consistency required.

The level of investment is fully justified by the high quality performances that the mixer guarantees in terms of repetitiveness of homogeneous color concrete for the face mix. This will definitely further strengthen DecoPave Co. Ltd. already excellent reputation in the South Korean market with new lines of products.

The final integration of the whole batching plant inside the customer‘s production building guarantees a continuous production even in the worse weather conditions well know during the harsh winter of the South Korean Region. This also shows once again the high level of customization of MCT Italy concrete plant solutions and the skills of the engineering technical team which has worked in a perfect synergy with all the other partners involved in this ambitious project.

Long-lasting Partnership

DecoPave Co., Ltd. CEO said: “The national industrial complex called ‚the heart of the manufacturing industry‘ is in a situation where the domino closes, but we affirm that there is no recession for SMEs armed with unrivaled technology. It will show Decopave‘s power.”

Mr. Park continued: “DecoPave has grown from a small company with a capital of 50 million Korean Won to a company with a value of 50 billion Won in just 7 years, with the idea that there is no recession in SMEs armed with technology.” “Nowadays it is difficult working in the construction industry. As we implemented the 100% process automation system we expect even more rapid growth.”

Meanwhile, DecoPave Co. Ltd. was selected as a ‚Hi Seoul Enterprise‘, an excellent company in Seoul supported by the Seoul Metropolitan Government and SBA (Seoul Industry Promotion Agency) in 2016, and acquired G-PASS certification and ISO 9001/14001 quality management system, Environmental management system certification, Procurement excellent product selection.

MCT Italy‘s South Korea Sales Director Falchetti Gabriele says that the plant MCT has delivered is the first of its kind delivered in South Korea for the high level of automation. During the past years, South Korea has gone through changes that have had a boosting effect on the construction industry as the new leaders tackle the nation’s problems. “In this part of the world, there is an increasing demand for special and innovative construction solution utilizing the latest general of special concrete. At MCT Italy, we help our customers adapting to the changing environment and to new business opportunities throughout the project.” Falchetti explains.

At DecoPave Co. Ltd. efforts are also being made for employee welfare. With the establishment and introduction of a smart factory, workers in the production plant can work 52 hours a week, and due to the nature of the Danyang region, dormitories are provided for workers from other regions. Currently DecoPave Co. Ltd is hiring talented people who will grow with companies in step with the introduction of smart factory.