Concrete products based on a binder matrix produced with low CO2 emissions

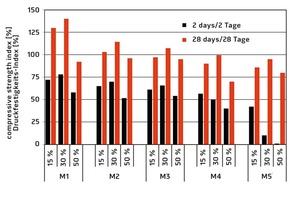

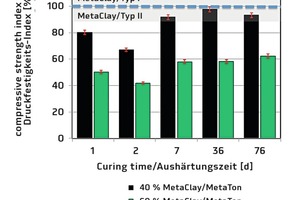

Cement production generates substantial CO2 emissions that adversely affect the environmental footprint of concrete. In a research project, cement was replaced with MetaClay, and a commercially attractive concrete paver was developed.

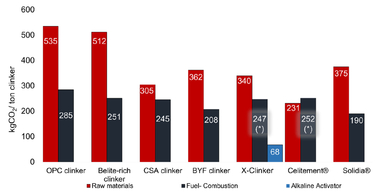

Cement production is characterized by process temperatures in excess of 1.300 °C and substantial CO2 emissions; about 60 % of these emissions are attributable to limestone neutralization [1]. These emissions deteriorate the carbon footprint, and thus reduce the commercial potential, of building materials that use cement as a binder, including concrete.

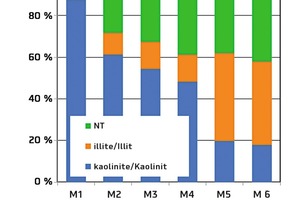

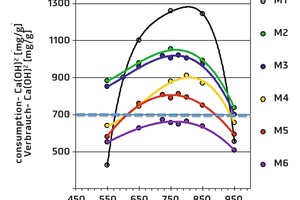

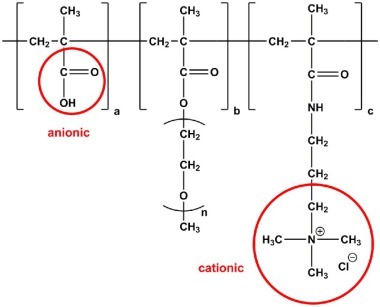

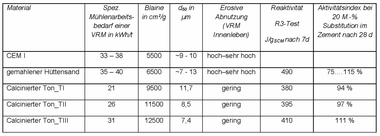

For this reason, the use of thermally activated clays or MetaClays as alternative binders in cementitious building materials has been investigated with great interest in the past few years. MetaClays are produced at much lower temperatures on the...