Precast Pad Foundation

The six Italian manufacturers of structural precast concrete elements Truzzi, Betoncablo, GED, C.A. Construzioni Antonioli di Bormio, Esse Solai and Rivoli form a group of companies named Monachino Technology. Together they carry out research and development projects. The group of companies is constantly looking for partners worldwide who are interested in manufacturing the group’s precast concrete products as licensees. The product portfolio includes a precast foundation for double walls, a precast foundation for a retaining wall, a retaining wall and a precast wall for tunnels and bridges.

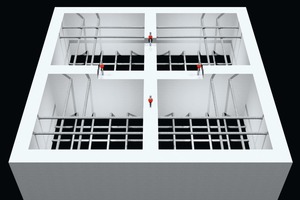

A prestige product is the precast pad foundation and the associated foundation system that is primarily used as a foundation for industrial buildings.

The precast foundation is a reinforced concrete element consisting of a tied rebar cage incorporated in a semi-precast concrete element which serves as formwork. The geometric dimensions and the steel area are subject to static calculations carried out according to the distributed loads N, Mx, Tx, My, Ty and the pt pressure admissible on the ground.

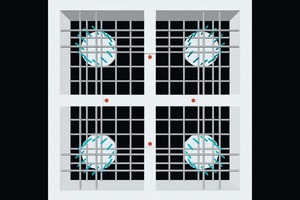

Precast Pad for deep foundations on piles or mini piles

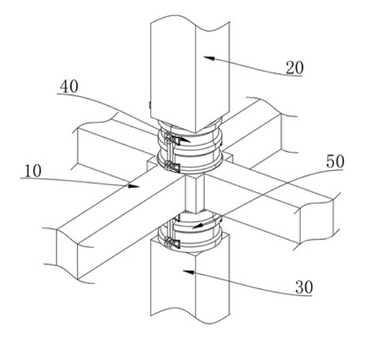

Figure 2 illustrates that the precast element may be mounted both in a shallow foundation and a deep one. When faced with conditions in which the admissible pt pressure cannot bear the N, Mx, Tx, My, Ty loads, piles or mini piles are inserted into the foundation.

The Precast Foundation can be produced in different shapes and dimensions to meet every design and structural requirement.

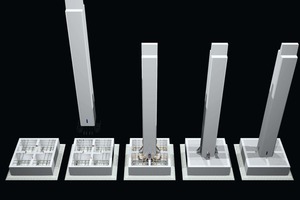

Assembly

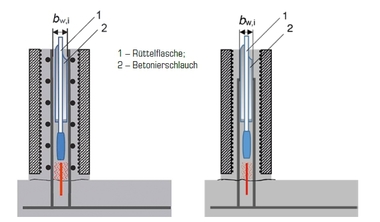

During the assembly process (see Fig. 3), the precast pad foundation is placed on the lean concrete, which has previously been prepared (Fig. 3, 1), then the precast column is mounted on the pad foundation and the bent rebars jutting out from the base (Fig. 3, 2) are inserted inside the foundation element (Fig. 3, 3). A final casting of concrete embeds the column’s rebars inside the precast foundation (Fig. 3, 4). The work is completed with the removal of all adjustment devices (Fig. 3, 5).

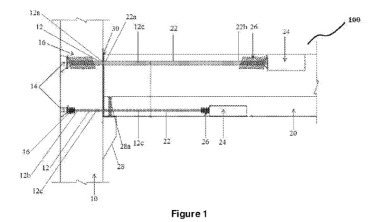

For the assembly and alignment of the precast column, adjusting devices are used. These allow an easy, fast and precise installation. During the production phase of the Precast Foundation, four anchor bolts are embedded in the central concrete walls (see Fig. 1), while the precast column is equipped with eight threaded couplings. The adjusting devices are fixed to the anchor bolts using nuts and to the precast column using bolts. This system not only allows the precast column to be aligned with pinpoint precision, but also eliminates any kind of shoring during assembly. The four connections will be dimensioned in relation to the weight and other strains to which the column is subject and are used merely for assembling the elements. When the concrete inside of the precast foundation has hardened, all the adjusting devices are removed.

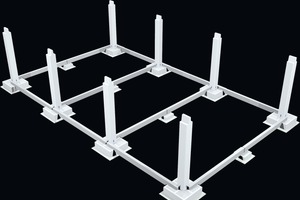

Connecting Beams

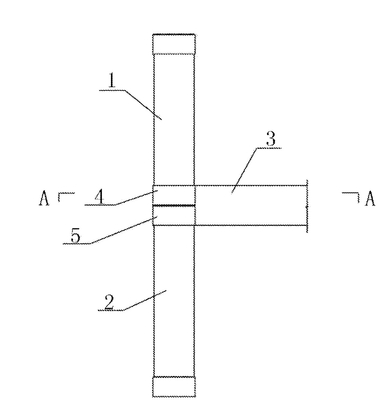

The precast element has been conceived and designed to obtain a perfect connection between the precast foundation and any connecting beams necessary for reducing the lateral and longitudinal strain caused by seismic actions on the structure. After assembling the precast columns, the connecting beams are connected to the foundations through the rebars that jut out vertically.

The connecting perimeter beams of the structure will also serve as panel beams for the precast panel and will therefore be dimensioned accordingly. In order to optimize the dimensioning of the connecting beams, little precast pads may be used in order to support the connecting beam at the center. The connecting beam can be precast or cast-in-situ.

The work is completed with a final casting of concrete into the Precast Pads, thereby connecting columns, beams and foundations.

No additional workers necessary

According to Monachino Technology, the costs for construction of a foundation can be reduced to half of the costs for a standard foundation when building with the group of companies’ foundation system. Another effect is that safety for workers on the construction site will be improved.

Furthermore, according to Monachino Technologies, when building with the foundation system described above it is not necessary to employ additional skilled workers or use auxiliary tools like formwork, boards, nails, hammers, pincers, shears, etc.