Large counterflow mixer installed in Denmark

When DK Beton, the concrete factory located in Avedøre, Zealand/Denmark that is part of the Heidelberg Cement Group, intended to modernize its facilities, the decision was taken in favor of Haarup Maskinfabrik A/S as supplier for the plant equipment. Whereas a 3,000/2,000 liter mixer had been used for the previous production, it was planned to replace the same by a new 6,000/4,000 liter mixer.

Due to the fact that the facility is situated amidst the Danish capital of Copenhagen, the new mixer had to be able to deliver ready-mixed high-quality concrete for discharging into trucks, as the short driving times do not allow for any final mixing periods in the truck mixer.

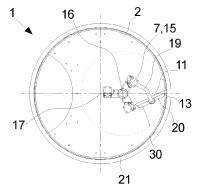

Therefore, DK Beton opted for the installation of the 6,000 liter counterflow mixer with two discharge units which is the largest one in the world according to Haarup. This means that a concrete mixer truck may be permanently available underneath the mixer while another mixer truck is being loaded.

31,000 m³ of concrete in just two months

The mixing plant comprises a bin system for 10 different aggregates dosing to two weighing belts, which is even possible simultaneously, if necessary. An inclined belt is transporting the aggregates from the weighing belts to a 6,000 liter hoist for carrying the aggregates into the new 6,000/4,000 liter mixer.

For powder batching the cement bins are equipped with screws, feeding two powder weighers. A frame is placed beneath three of the total of six bins providing space for storing the admixture hoppers, pumps and other things. Six different chambers are available for admixture batching including the associated admixture weighers for discharging into the mixer at the respective time. A water weigher combined with a flow meter enabling fine batching is used for water dosing.

At the beginning of August 2014, the plant was put into operation, while the installation caused a downtime of only four days in total for the factory. The production output already amounted to 31,000 m³ of concrete just two months later.

After commissioning Jørn Dam, Technical Manager at DK Beton, positively commented: “We are very impressed on the precise batching tolerances the new plant obtains.” General Manger, Niels Søndergaard-Pedersen, added: “We are very proud of our new plant and are very pleased about the good cooperation of all partners involved in the project.”