Important parameters for coloring concrete

Coloring concrete has long since ceased to belong into the “new concrete technology” category. Some important parameters should be taken into account in the process, such as the color of the pigment and the proportion of gray in the cement. There are other factors, however, that only become apparent at second glance.

Concrete is a construction material that offers an exceptionally wide variety of different design options. Not only can it be molded into almost any given shape, but its surface texture and color can also be modified. Fluctuations in both mix design and production factors need to be minimized, however, in order to ensure that a structure will have a consistent color shade.

Coloring concrete has long since ceased to belong into the “new concrete technology” category. Some important parameters should be taken into account in the process, such as the color of the pigment and the proportion of gray in the cement. There are other factors, however, that only become apparent at second glance, such as the amount of water removed from the concrete by the formwork used.

Inorganic, synthetic pigments

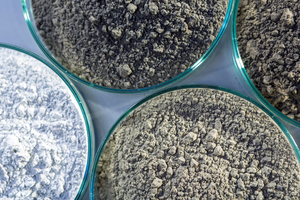

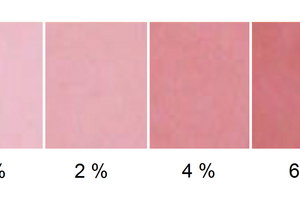

According to DIN EN 12878, inorganic, synthetic pigments are used to color construction materials made of cement. They need to be resistant to sunlight exposure and the effects of weather and can be applied as powder, liquid or granular material. The added quantity is calculated in relation to the cement content. In the process, it should be borne in mind that the color intensity initially increases in line with the amount of pigment applied, but stagnates above a certain percentage – the color saturation level.

The market offers a certain number of different pigments, which can be mixed to achieve the desired shade. However, the actual appearance needs to be tested under real-world conditions. This means that sample slabs must be manufactured using the same type of cement, aggregate and other materials. Another important quality criterion of pigments is their color strength, which describes how well they are capable of transferring their inherent color to the medium to be colored. This can be an important factor in terms of cost-efficiency.

Another factor to be taken into account when selecting the suitable pigments is whether they are intended for use in reinforced or non-reinforced concrete. In the case of steel-reinforced concrete, the concrete colors must not exceed a certain chromium content; otherwise there is a risk that the reinforcement will corrode.

Cement color

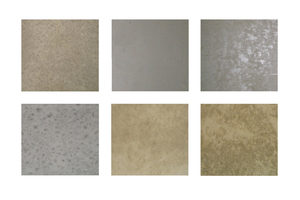

An important aspect to be considered when coloring concrete is the color of the cement used. Depending on the mining area and production method, its color can range from light to dark gray and even reddish brown. The lighter the color of the pigment, such as yellow, the more important is the color of the concrete or cement to be used. To achieve exceptionally brilliant colors, it is often necessary to use white cement, which is very low in iron and impresses with its bright white color. This allows a wide variety of colors to be realized in the concrete, and even extends to mixing white cement with black or gray pigments for some structures to achieve a specific shade of gray.

Aggregates

Amounting to approx. 70 % by volume, aggregates account for the largest proportion of the concrete mix design. Although they are normally completely enclosed by the cement paste, they may still show through the paste, or the top layer of concrete may weather over time. The aggregate used should therefore also be considered when determining the concrete color. The color of the aggregate is particularly important where the top layer of cement is deliberately removed, as is the case, for example, when sandblasting, acidifying or bush-hammering. In this case, the color of the concrete and the color of the aggregate blend together in the eyes of the observer – often a desired effect. In these situations, it is recommended to produce the concrete using an aggregate in the desired color.

Mixing, formwork and release agent

In order to achieve a uniform color result, the concrete color must bond well with the other concrete components. It is therefore recommended to first add the pigments to the aggregate and mix for about 25 to 40 seconds. Only then should water, cement, etc. be added. The most homogeneous results are achieved in a compulsory mixer. Adding the color in a truck mixer may result in color variations on the concrete surface.

As soon as the cement comes into contact with water, fine crystal needles form and interlock with each other, causing the concrete to harden. In this process, the correct mixing ratio of water and cement (w/c ratio) is of particular importance for the hardness and inherent color of the concrete. The larger the w/c ratio, the more pores form in the concrete. The pores scatter the light and result in the concrete appearing to be lighter in color. This fact needs to be taken into account not only for the concrete formulation and the addition of plasticizers, but also for the formwork. Absorbing formwork, such as timber, removes water from the concrete, which in effect results in a lower w/c ratio. Absorbing formwork is well-suited for pigmented concrete, but makes it appear slightly darker in color. Non-absorbing formwork involves the risk of pore and marbling or cloud formation.

Release agents can have a tremendous impact on the appearance of the concrete. This is why preliminary tests need to be performed, and it is essential to always use the same release agent for an exposed concrete building. Incorrect application of the release agent is a common mistake. The formwork needs to be fully and evenly treated with the selected product. An excessive use of release agent may result in unesthetic discoloration and, in the worst case, in uneven hardening of the concrete.

Hardening conditions/curing

Concrete hardens as a result of the cement paste forming crystals of varying sizes. Higher hardening temperatures typically lead to finer crystal needles. The size of the crystals has an effect on how strongly the light is scattered when striking the concrete. Fine crystal needles scatter the light more effectively than coarse ones, which results in the concrete appearing to be lighter in color. However, this phenomenon is visible to the naked eye only when the difference in temperature has reached a certain magnitude.

To protect the concrete in the long term, a hydrophobic finish and/or graffiti protection can be applied. It is important to know, however, that these may also have an influence on the appearance of the concrete surface. Some products create a certain luster, which is clearly visible depending on the position of the sun.