Guidance on the design and installation of paved concrete gutters (Part 2)

Gutters are components whose construction requires both designers and contractors to possess the necessary expertise and many years of experience. This article is the second of a series of two contributions setting out to describe the most significant errors and shortcomings in the design and construction of paved concrete gutters in order to minimize them.

2.1.3 Concrete pouring and dislocation of paving blocks

In addition to the inappropriate on-site storage of the concrete, the concrete is usually not compacted to a sufficient extent after placement. Compaction usually takes place by “tamping with the workers’ boots” (see boot prints in the Part 1 right picture of Fig. 11). This procedure results in a superficially dehydrated, insufficiently compacted concrete of dry consistency as the base of the gutter (see Fig. 13). Yet the story does not end at this point: To drive down costs even further, no bonding agent is applied to establish at least a certain degree of adhesion between the foundation concrete and the gutter paving stones, as shown in Fig. 12.

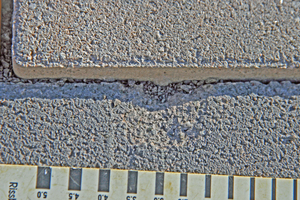

Thus, no sufficient bond between the paving stones of the gutter system and the foundation concrete is achieved so that such gutters often crack at regular intervals (more often than not, at distances of 1 to 2 m perpendicular to the gutter routing) either only in joints or, sometimes, also affecting the paving blocks as such (see Figs. 14 and 15).

Such cracks are usually relatively narrow, and experience shows that the risk of major consequential damage appears to be manageable nonetheless.

2.1.4 Concrete compaction for lateral support

By way of example, the issue of insufficient compaction becomes particularly apparent in the lateral support zone of curbs. However, the problem is of a systemic nature in this case. In practice, lateral support concrete cannot actually be compacted in an appropriate manner due to the installation environment. This concrete is thus usually poured against the soil and only “compacted” manually using a shovel (see Fig. 16).

This method will inevitably result in a substandard quality of the concrete and a poor bond between the concrete and the curbstones. Consequently, the backup sometimes only provides low resistance to the shear forces introduced by vehicular traffic, depending on the overall structure, which is why it will be dislocated when subjected to higher loads, as shown in Fig. 17 for the surrounds and edge blocks of a pavement normally subjected to comparatively small loads.

It thus appears unfortunate that the new ATV DIN 18318 does not specify any requirements for the structural strength of the lateral support concrete. Instead, the new standard only stipulates that

a C 20/25 concrete should be used for establishing lateral support to block pavements subject to vehicular traffic, whereas

a C 16/20 concrete should be used for establishing lateral support to block pavements not designed for vehicular traffic.

A high-quality concrete specified in the order will not necessarily result in a high structural quality, which particularly applies to foundation and lateral support concrete. This is why the approach taken in the ZTV Pflaster-StB appears to be more meaningful (irrespective of the level of compressive strength to be provided by a fully functional lateral support). This guideline continues to require a certain concrete compressive strength to be ensured by structural means (in this case, 12 MPa). However, such a high compressive strength can normally be achieved consistently only if the lateral support concrete is poured into sufficiently rigid formwork and if appropriate compaction takes place.

2.2 Movement joints

2.2.1 Revision of joint liners

Choosing the right material for movement joint liners is not the only key criterion for ensuring the long-lasting performance of the gutter. In addition, when assessing specific cases of damage, we find that liners were frequently reworked by applying cementitious materials. As soon as (temperature-induced) movements occur in the structure, such materials will break out of the joint, resulting in the very unsightly appearance shown in Fig. 18.

2.2.2 Transition from bonded gutter to unbonded concrete block pavement

The transition from a bonded gutter to an unbonded block pavement should be separated by movement joints. Omission of such joints will significantly increase the risk of edge breakage in these areas because the pavers laid in an unbonded structure often do not have sufficient positional stability, which is why they are pressed against the bonded gutter, leading to corresponding damage in this zone (see Figs. 19 and 20).

Incidentally, such edge breakouts also occur when the transition is filled with jointing mortar. However, these are shifted by one row of stones.

Deviating from currently applicable standards and guidelines, the positional stability of the last row of unbonded paving blocks should thus also be ensured at least by installing a lateral support concrete layer or, better still, a surround.

2.2.1 Obstruction of movement

The risk of cracking in bonded gutters also increases if the free movement of the bonded gutter is impeded in certain places. This is the case, for example, in the area of drains, which is why additional movement joints must be provided here (see Section 1.2). In a similar manner, however, temperature-induced movements of the paved gutter can also be obstructed at certain points by mortar interlocking in the joints between the curbstones so that cracks occur in the joints or paving stones of the bonded gutter (see Fig. 21).

2.3 Jointing mortar

2.3.1 Scaling of jointing mortar

The jointing mortar used for constructing the gutter has a flowable consistency, and the paving block surfaces are cleaned with water to ensure an appealing appearance. If excessive amounts of water are used during cleaning or if the mortar settles too much due to an exceedingly “soft” consistency, this will significantly increase the risk of scaling of the near-surface mortar in the use phase of the gutter. In many cases, such damage does not occur on the entire surface of the gutter system. Rather, it mainly occurs in isolated areas (see Fig. 22).

Massive scaling of the jointing material is most often associated with exceedingly small joint widths. In such narrow joints, the ability of the grout mortar to fill the joint completely is limited. If freeze-thaw loads act on the joints, the jointing material often weathers out very quickly and sometimes disappears completely (see Fig. 23).

In addition, if a mortar unsuitable for the filling of joints in bonded structures is used (see the explanations on self-mixed mortars in Section 1.3), damage to the mortar may also result in some cases, rendering it almost completely unusable (see Fig. 24).

3 Crack repair in stormwater runoff gutters

Cracks occurring in paving blocks of gutters often give rise to disputes between the client, the contractor and the material supplier. In addition, visual imperfections are frequently “improved” for the worse by gutter rehabilitation measures. For this reason, the technical necessity of crack repair and its usefulness will be briefly discussed in conclusion. First of all, it is worth noting that cracks cannot be avoided completely when applying the bonded construction method. The new ATV DIN 18318 standard thus guides that isolated cracks occurring, for instance, due to creep and shrinkage are permissible provided that their width does not exceed 0.8 mm.

If (even very narrow) cracks form in the concrete paving blocks of gutters, clients frequently demand that these cracks be cut open and filled with resin – even though such narrow cracks are often completely negligible from a technical point of view. In addition to the costly nature of such repairs, cracks closed using this method will normally be much more visible than in their previous condition, as the image in Fig. 25 shows.

REFERENCES/LITERATUR