Flexible tilting table production and modernized reinforcement preparation

Having invested in new tilting tables and modernized reinforcement preparation, Zitzmann Baustoffe-Betonwerk GmbH produces ceiling slabs, walls, structural precast components, concrete blocks and pavers made to measure in accordance with the customer’s requirements.

Since its formation in 1949, and in keeping with its philosophy, “Intelligent design, individual solution, reliable implementation”, Zitzmann Baustoffe-Betonwerk GmbH based in the Eastern Bavarian town of Cham has developed into a strong medium-sized partner for all matters related to construction. Combining traditional values and the striving for continuous improvement, the company has been able to achieve and retain the performance leadership in Eastern Bavaria in the building materials trading, ready-mixed concrete, precast concrete production and residential construction sectors, along with a construction elements, gardening and landscaping exhibition as well as its own DIY store. In the field of precast concrete production, the company covers a wide range of different products: ceiling slabs and walls, structural precast components, as well as concrete blocks and pavers.

The company has always remained loyal to its roots, producing precast concrete elements exclusively at the Cham headquarters even today. As a result of the positive business development, Zitzmann Baustoffe-Betonwerk GmbH has expanded in recent years to include locations in Regensburg, Schwarzenfeld and Pilsen in the Czech Republic.

Investment in flexible tilting table production

“Made-to-measure customer solutions require made-to-measure production methods,” says Operations Manager Thomas Oberberger, explaining the Zitzmann Group’s recent investment in the continued expansion of precast production. In order to be able to respond to customer requirements even more specifically in the future and to manufacture customized concrete elements in wall production, the company has expanded its in-house precast concrete production, in collaboration with formwork expert Tecnocom, a member company of the Progress Group, to include tilting tables measuring 16 m in length and 4.5 m in width each, thus enabling custom sizes to be produced even more easily than before.

The hydraulic lifting system with three telescoping cylinders ensures safe and steady tilting of the tables which can be loaded with up to 700 kg per m² and are used for the production of elements measuring up to 450 mm in thickness. All of the tables are equipped with a hot-water heating system to speed up hardening of the precast elements.

Thirteen vibrators per table provide for a uniform and high-quality compaction process on the finely polished shuttering plates, making them ideally suited also to the production of complex exposed concrete surfaces. “As a result of this investment”, explains Oberberger, “we will be fully equipped also in the future to handle the most complex customer projects – in terms of both quality and made-to-measure product sizes.”

Modernization of reinforcement production

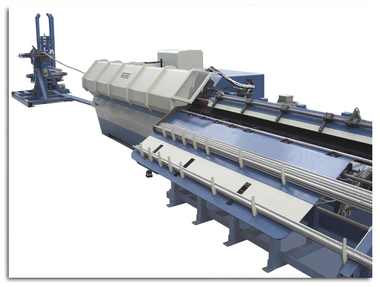

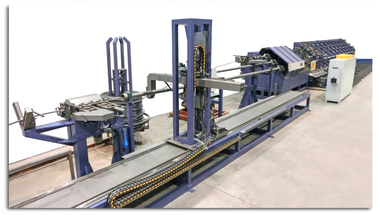

Zitzmann focused not only on setting up the new, flexible tilting table production for customized parts, however, but also on modernizing the existing reinforcement production for its own precast concrete plant. The company therefore decided to invest in fully electric multi-strand wire straightening and cutting machines of the MSR series – one MSR 16/5 multi-rotor and MSR 20 each – and in an EBA S16 Plus automatic stirrup bending machine from Progress Maschinen & Automation, also a member of the Progress Group.

The MSR 16/5 multi-rotor machine for straightening the reinforcing steel off coil features five separate rotors, meaning an independent rotor for each wire diameter. Wire diameter changes are performed fully automatically and within mere seconds by simply repositioning the rotor table. All wire diameters are placed in the machine and available “just in time”.

The tried-and-tested rotor straightening technology from Progress is based on a separate feed for wire transport and on the use of straightening nozzles inside the straightening rotor for the straightening process. Exceptionally gentle handling of the wire surface, exceptionally low-wear operation of the machine and a consistent result of the straightening process are ensured by the slight offset of the straightening nozzles for each wire diameter and by synchronizing the rotating speed of the rotor with the wire feed rate. The straightening nozzles do not require maintenance.

With the MSR 20, Zitzmann is complementing this step of production by a machine processing wire thicknesses ranging from 8 mm to 20 mm.

The Progress EBA S line covers applications in the wire diameter ranges of 6 mm + 12 mm, 6 mm + 14 mm, and 6 mm + 16 mm. This most recent generation of machines impresses with exceptional flexibility paired not only with high precision and performance but also with low costs for operation, maintenance and wear parts. Yet another benefit: the machine features a servo-electric, entirely non-hydraulic drive system.

The modernization measures have resulted in an increase in productivity and quality at reduced maintenance and wear costs.

Conclusion

Looking back, Operations Manager Oberberger is satisfied with the investments made: “Tilting table production will help us in the future to improve the manufacture of customized and high-quality precast concrete elements and to further strengthen our market position. Both for the new investment and during the modernization of our reinforcement production, we have collaborated with all of the companies of the Progress Group in a pleasant, cooperative and results-driven atmosphere, which enabled us to successfully realize a solution optimizedfor our requirements within an excellent time frame. This investment has enabled us to not only improve the quality of our products; we also expect an increase in production of around 15%, which is attributable to the powerful steel-processing machines.”