Flexcaster and Sidecaster for the production of precast concrete stairs

The Construx hydraulically adjustable stair molds are by far the most versatile available on the market. They come as a horizontal (Flexcaster) or a vertical (Sidecaster) version. The most common are the horizontal molds, the Flexcasters. These molds are suitable for producing straight stairs upside down (steps facing downwards).

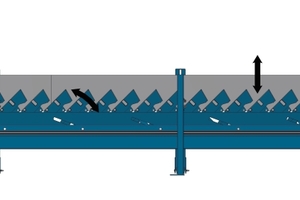

The hydraulic controls make the setting of the mold as easy as it can get. A hydraulic unit operates two horizontal cylinders in order to adjust the distance in between the individual steps. The same hydraulic unit also controls two vertical cylinders, which adjust the angle between the steps. Consequently, both going and rise of all steps are simultaneously hydraulically controlled.

Simultaneously hydraulically controlled

Usually, the width of the stair mold is 1,5m, but this can be wider, e.g. 2m, 2,5m, or even up to 4m. In the wider molds, two stairs can be cast next to each other. Customers can choose any number of steps, but the number usually varies between 16 and 24. Long molds with 20 steps or more can be used to cast simultaneously two flights of stairs with a limited number of steps. One side of the stair mold is equipped with a height-adjustable side panel. As a result of this height adjustment, the steps may vary in thickness between 120mm and 250mm. For wide stair molds, an extra adjustable side panel on the other side is an appropriate option.

The stair molds include two sets of landing equipment (top and bottom). The panel for the bottom landing is constructed as an extended first step element. The position of the bottom landing panel can be hydraulically adjusted. The panel for the top landing sits on a carriage and can be inserted at every position after removing a step. If the top landing carriage is set up at the rear of the mold, it will be linked to the last axle, thus travelling back and forth when the goings and risers are hydraulically adjusted. The angle of the top landing panel can be controlled manually with great precision by means of two synchronised high-precision spindles. In addition, the mold can be supplied with an extra top landing panel that can be fitted anywhere in the mold, without the need to remove any steps.

The steps can feature several different designs:

Straight steps,

Steps with cut-back,

Steps with cut-back and nose.

Budget-friendly alternative

In order to produce these three different features, the step elements are designed with an articulating (2 positions) support plate which falls back 18mm (or 21mm), incorporating timber blocks and magnets. These blocks and magnets can accommodate 18mm (or 21mm) plywood strips, or 3mm laser-cut steel plates onto which 15mm (or 18mm) plywood strips are screwed. When two complete sets of these 3mm steel plates are supplied, one set will be in use in the mold whilst the other set can be prepared in order to be used the next day. The steps with cut-back and nose can be produced by using triangular magnetic chamfers. As a standard feature, the goings are adjustable between 200mm and 320mm and the risers are adjustable between 150mm and 200mm. Other minima and maxima are possible.

The use of hydraulic hand pumps is a budget-friendly alternative to this fully hydraulically adjustable stair mold.