Precast CAD: Planning, presenting

and producing efficiently

When using the degree of automation as a yardstick, the precast industry is spearheading the trend in the construction sector. There is hardly any other sector in which the interlinking of digital design and production data is equally far advanced. This article reports on CAD and CAM opportunities, trends and developments.

In the past few years, prefabrication and precast construction have become increasingly significant. One of the main reasons why this happened is the increased cost and time pressure associated with the erection of buildings and structures. Precast elements can be manufactured for a wide range of applications quickly and efficiently in almost any conceivable dimensions, shapes, colors and surface textures. Series production increases cost efficiency and manufacturing quality but also reduces production and construction times. Industry-specific software has been used for many years at precast plants in order to ensure a high quality standard and efficient workflows and to continuously streamline the process.

From CAD to CAM: streamlining processes in precast construction

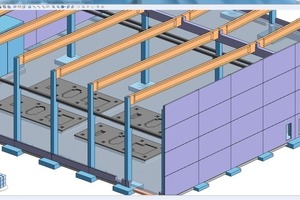

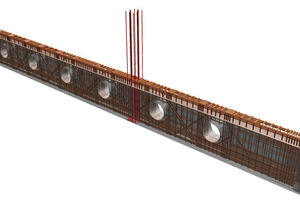

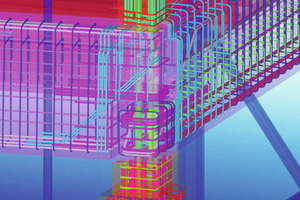

Design and production need to be increasingly quicker and more flexible in order to adhere to tight design lead times at the plant, to ensure a product range that is as varied as possible, and to appropriately respond to short-term changes communicated by clients. Today, software providers offer a broad range of programs specifically developed for the precast industry in order to equip precast plants to master these challenges. Industry-specific software covers the design and construction, costing and visualization of precast components but also the scheduling of manufacturing, delivery and assembly, as well as features for invoicing, administration and controlling. For design and construction in particular, such programs have become indispensable tools in the precast industry: First of all, automated production cannot do without electronic component data. Moreover, data relevant to production, such as (reinforcement) plans and lists, steel quantities, concrete volumes or weights can be generated efficiently only when using a computer. Element variations can be developed much more quickly and efficiently than on the basis of conventional methods. In addition, precast elements can be optimized in structural and formal terms, which reduces concrete and steel consumption but also production costs whilst enhancing both design and product quality. Precast plants are the assembly line type production facilities of the construction sector because, similarly to the automotive industry, precast elements are manufactured using centrally controlled robots. For this purpose, the control computer of the plant reads CAD information transmitted from the design department, converts it to machine data and transfers it to the production line. This control computer serves as the link between the CAD design data and the CAM production process and operates the entire production line, including pallet occupancy, production sequence, machine control, pallet transport, and curing times. Process charts provide the complete range of information pertaining to the entire production line and enable continuous monitoring of all work stations and production processes. The production line includes pallet circulation systems or shuttering robots used for the manufacture of large, extensive precast elements, as well as reinforcing units for cutting, bending and inserting reinforcing steel.

Automated routines streamline the design process

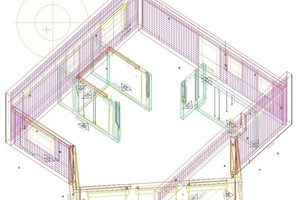

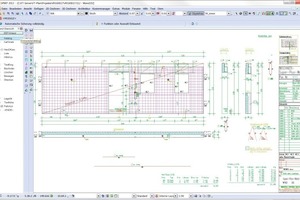

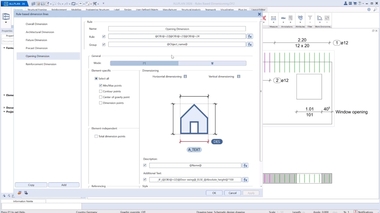

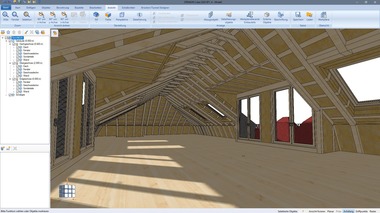

In very much the same way as in production, the design of precast elements utilizes the benefits and opportunities provided by the use of computers. For instance, precast plants use the plans submitted by the architect or structural engineer to re-enter the relevant structural components into the system or to transfer them more or less completely via data interfaces, and to automatically create an element-based layout thereafter. In this process, the program automatically considers requirements pertaining to structural and architectural design and building services, such as the division in the contact zone between wall units or the omission of such a division where openings or embedded parts are located. Slots, penetrations, minimum/maximum element dimensions and other features are also considered, as are, for instance, the requirements associated with inserting a cable conduit system. Obviously, divisions can also be introduced or modified manually at any time. Assembled or cast pipes and transport anchor positions are also determined automatically depending on the center of gravity. CAD systems allow for the design of simple solid walls, multiple-shell walls, sandwich elements or brick walls, as well as for the detailed design of solid, precast, ribbed or hollow core floors. Floor supports are automatically determined on the basis of the wall thickness and direction of installation; upstands or floor openings are defined manually. The automated element division feature also considers edge attributes such as support dimensions, surfaces and rebar overhang. The slabs are dimensioned accordingly, and a position number is allocated to each slab. Mesh reinforcement is shown on cutting drawings considering an optimized off-cut pattern. Precast concrete stairs belong to the most complex category of building elements due to their customized geometry and shape, which is why the CAD design of asymmetrical stairs is exactly the right method to open up an enormous streamlining potential. When the determining factors (staircase geometry, floor heights, floor/stair structure) have been identified, the parameters of stair flights, main and intermediate landings and supports are defined. The program uses this information to automatically generate a 3D stair model whilst checking compliance with rules and standards, as well as the step length or headroom along the walking line. The stair parameters shown in a dialog box can be modified in order to respond to specific needs, which means that customized stair shapes are also possible to a certain extent. Designers may resort to conventional CAD tools if the stair geometry significantly deviates from the standard or if specific details need to be included.

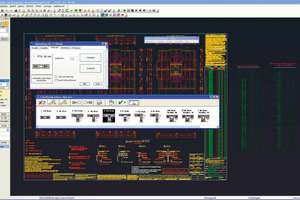

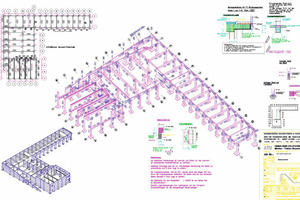

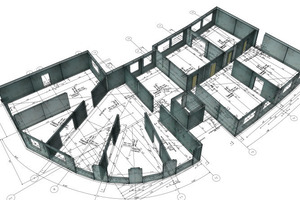

From 3D component to 2D plan – or 3D PDF

Any analysis relies on the central, three-dimensional CAD data model, which contains not only geometrical information but also descriptive, alphanumeric data (e.g. concrete grade and surface). This information can be used to prepare manufacturing documents and all quantities and volumes required for costing, quotations and purchasing. The required effort is reduced in the case of changes because the precast components interact with adjacent objects and thus respond to changes made to these objects. If a column is relocated, the related beams, connections and drawings are also updated automatically. The same applies to the relocation of openings, or an increase or decrease in their size: the associated central and lateral reinforcement is adjusted automatically. However, all these features work only with standard components. Such automated routines are usually not sufficient for customized objects and complex interactions between the design, structural framework and building services, which is why manual review and revision is required. The three-dimensional element can be exported as a 2D or 3D PDF file and presented “off-line” or on-line, which significantly accelerates the coordination process between the parties involved. The observer may randomly move and turn 3D elements, view them in detail from all sides, and zoom into and out of them without having a CAD program installed on his computer (see also BFT 11/09). In addition, random sections can be generated and dimensions requested in the 3D PDF file. Once the CAD element has been approved as being consistent by all parties involved, the actual reinforcement, shuttering, production and site documents are generated automatically. They contain the element drawings, including dimensions, labeling and visualization of the reinforcement with extract drawings. Other parameters determined include area, weight and required concrete volume. If short-term, simple changes become necessary, such as to the reinforcement, a surface attribute or the geometry of the slab, all modifications are also introduced directly to the model and thus to the installation plan. The installation plan includes a top view, a 3D view, a stamp field and all details relevant to assembly, such as the amount of mortar needed on the construction site. Dimensions are added to the precast components in a fully automated process but can be changed and complemented manually as and when required. The same applies to the plans, which can be complemented by texts, hatchings, color codes etc. in the CAD software.

No data flow without interfaces

A fully functional data exchange is crucial for ensuring a smooth design and production process. Various interfaces are used for this purpose. The standard exchange formats DXF or DWG serve to import the building data submitted by the architect or structural engineer. The geometry is often re-entered completely since the quality of the data may differ significantly – reaching from simple 2D lines to element-based 3D building information – and a high amount of building information gets lost in the process of data interchange. In line with the growing significance of Building Information Modeling (BIM) systems, i.e. object-oriented building data modeling, so-called IFC basic data models conceived by the association BuildingSmart e.V. (www.buildingsmart.de) are used. These models largely eliminate the counter-productive multiple entry of components whilst ensuring a more efficient data flow. Interfaces are also required to exchange data between the technical CAD program and the ERP applications of the business on the commercial or logistics side. ERP (Enterprise Resource Planning) programs provide tools for resource planning and control, including bids and quotations, purchasing, warehousing, dispatch, human resources etc. Aside from a functional interface between CAD and ERP, data interchange with PPC (production planning and control) and factory floor data collection systems is becoming increasingly important.

CAD market and trends

A significant number of renowned providers offer design and engineering programs specifically conceived for the precast industry (see information in separate box) but some of these offerings differ significantly in terms of their concept, functionality and price. The provided software packages can be divided into three categories: construction-specific architectural CAD programs with a precast add-on, general CAD programs with precast modules, and precast programs designed exclusively for this purpose. Architectural CAD systems provide benefits whenever complete buildings (instead of individual components) need to be represented either in 2D for drawings or three-dimensionally for quantity analyses and visualizations. General CAD programs with precast modules are in an “in-between” position because they enable a consistent 3D-based design of precast elements but do not offer an extended range of architectural features. Although “real” precast design programs generate standard precast elements at an unrivaled speed by establishing a parameter-based element description, most of these programs provide only limited options for free element design. The choice of the most appropriate solution depends on the specific range of applications and on the product portfolio offered by the precast plant, as well as on the existing system environment. Undoubtedly, one of the current trends is Building Information Modeling (see BFT 1/12), which is gaining ground not only in precast but also in the entire construction sector. BIM can render workflows more efficient, increase productivity and improve design quality. If BIM is used consistently, 10 to 30% of time and cost can be saved compared to the conventional approach. Due to the widespread use of this new working method in the individual areas of building design, BIM data can be used for investigations related to building physics but also for building services design, costing and cost control, construction scheduling, the optimization of structural frameworks using the finite-element method, or the optimization of the building design in terms of its energy efficiency.

“Marginal aspects” are also important!

From a functional point of view, precast CAD is getting ever closer to conventional CAD systems, which is why the equally important “marginal aspects” should also be considered when choosing the appropriate software. First of all, this relates to the software supplier/provider. In an ideal world, the client should enter into a long-term relationship with the provider, including software adjustments, updates/upgrades, maintenance agreements etc. – reason enough to look more closely at the provider’s position: Since when have they been active on the market, and what is their current commercial and financial position? How many licenses are in use? How good is the support offered, and how quickly are individual requests dealt with, software upgrades implemented etc.? The program should be flexible and provide for modular extension in order not to purchase unnecessary features in the initial phase whilst retaining the option of implementing customized extensions at a later stage. The use of CAD results in savings but also requires considerable time, particularly during the migration or familiarization phase, which usually takes several weeks. Amongst other things, how well users cope with the software depends on the aids provided, such as the user manual, tutorials, training, and the actual software support. Moreover, the choice of the right hardware is crucial but any state-of-the-art, Windows-enabled personal computer with a high-resolution, large LCD screen is well-suited for creating a CAD work station (coming at a price of about €1,000). A4 or A3 printers are needed for printing out lists whereas the printout of installation plans requires large-scale A0 output devices (requiring an investment of €500 or €5,000, respectively). Compared to the total cost of a complete production line without factory building (€10 to €12 million), the cost of the CAD software is more than modest and ranges from €5,000 to €10,000 per work station, depending on the program and installed range of features. In the case of add-on applications that complement a basic CAD program (e.g. AutoCAD), the price of the basic CAD system usually needs to be added to the price to be paid for the add-on. Subsequent costs not to be underestimated include specific software adjustments, training associated with new versions, maintenance agreements, and software updates and upgrades.