Automation and software for precast operations of US producer Taracon Precast

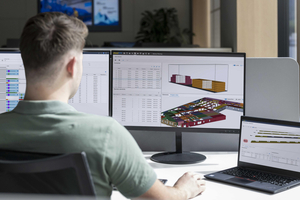

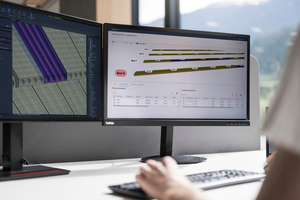

Taracon Precast, a Minnesota-based US precast producer, is a prime example of how digital technologies can impact planning and production in the precast industry. Using Progress Group’s plug-in for Autodesk Revit, BIMpro, among other features, they were able to maximize the efficiency of their planning processes, which benefits architects, structural engineers, and production teams. The time required to import planning data has been reduced significantly, thus streamlining the collaboration process and cutting planning time to just two hours from the previous eight hours. In addition, planning data is transferred in real time to manufacturing facilities such as production beds and machines, which enables Taracon Precast to respond flexibly to changes during the project.

Software, automation, and system integration

Progress Group is one of the pioneers in the digital transformation and automation of the precast concrete and rebar industries. The company seamlessly blends machine automation solutions with cutting-edge software while integrating the latest technologies, such as the Internet of Things (IoT), digital twins, robotics, cloud computing, and artificial intelligence, along the entire process chain from the drawing board to the final precast component.

Taracon also benefited from integrating the AheadAPS system, which also contributes to optimizing processes by enabling seamless planning of project phases, assembly sequences, deliveries, and bed layouts, including kitting, bed labor, and finishing operations. This platform integrates CAD, ERP, and MES systems to create an end-to-end digital process architecture.

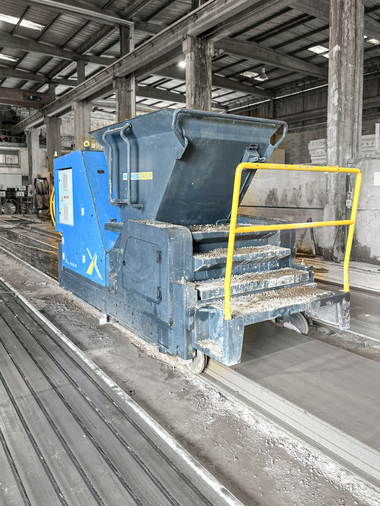

Taracon Precast’s plant upgrade also included the installation of an automatic plotter from Echo Precast Engineering, another Progress Group member. The SmartJet plotter draws and prints data such as cutting lines, project labels or areas to be cut out directly on top and on both sides of precast elements to prepare them for the next work steps.

Paul Nelson, Taracon Precast’s Vice President, emphasizes the software’s benefits, noting, “The efficiency and economy brought to our precast layout by the Progress Group software not only saves considerable costs over the project’s lifespan but also enables us to keep projects on schedule and respond flexibly to changes.”

Integrated approach brings measurable results

Progress Group takes an interdisciplinary approach. Their own rebar shop and precast division, as well as a cutting-edge software development team, provide the basis for the company to focus on end-to-end implementation. Progress software solutions are based on three major components: CAD for unparalleled design accuracy, ERP for seamless resource planning, and MES for managing and controlling manufacturing processes. Progress Group’s software portfolio, which includes BIMpro, Erpbos, AheadAPS, Ebos, Profit, and Stabos, ensures the consistent integration of all business processes and production workflows.

The proof is in its quantifiable efficiency gains: Using the above software solutions can reduce the time spent on planning and design by up to 75%. Architectural models can be converted into production-ready precast models with just a few clicks, which streamlines reinforcing processes and facilitates the generation of producible PXML data for direct machine use.

“All in all, I think Progress Group is the only company wecould have partnered with due to their shared vision of the future and how they can incorporate work instructions into machine data files to eliminate human error along the way.” — Alan Cartwright, Taracon Precast’s TQM Director.

CONTACT

Taracon Precast

6189 170th St N

Hawley, MN 56549/USA

+1 218 4988507

Progress Group

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979 900

info@progress.group

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

T +39 0472 979159

Echo Precast Engineering NV

Industrieterrein Centrum Zuid 1533

3530 Houthalen/Belgium

+ 32 11 600800