25th anniversary of R&W – a quarter century of innovation

Since its founding in 1998, R&W Industrieautomation has become well established as a supplier of customer-specific software solutions for machine control systems and plant commissioning in various segments of industry. These include concrete block production, chocolate production, foundry systems, pellet plants etc.

The year 2001 marked an important milestone in the company’s history, when R&W began to develop its own measuring systems for quality control in the concrete block industry. The basis for these systems was the far-reaching knowledge of Uwe Rahn as software developer and commissioner of concrete block plants.

On the basis of these many years of experience and deep insights gained into the production processes, the company developed block-height measuring systems specifically tailored to the requirements of its customers – with the objective of offering functional, sustainable and, above all, operator-friendly design. By now, these systems (SHV200/SHV500) have become well established worldwide and serve many companies as useful tools in production of high-quality concrete products.

The measuring systems were extended by integration of weighing systems to determine product density and strength. Since 2011, R&W has likewise supported the application of RFID technology for production boards, making it a pioneer in applying this technology.

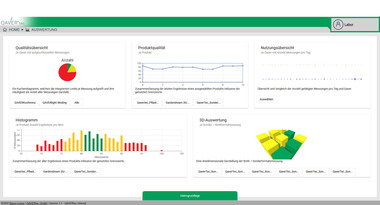

Encouraged by customers’ ever-increasing demands for quality, measuring systems (SHV200/SHV500) from the R&W team were further developed to a state-of-the-art laser- and camera-supported 3D Inspection System.

This system enables not only precise measuring of block heights, but also detection of surface defects, break-outs, voids and stains on concrete blocks. Aided by artificial intelligence, this system sets new standards of automatic quality control. This measuring system, now patented, makes a significant contribution to reducing rejects in concrete block production – resulting not only in cost savings, but also in enhanced quality assurance, environmental protection and sustainability. In addition, the system provides comprehensive tools for analyzing recorded production data, and existing measuring systems (SHV200/SHV500) can be upgraded to a 3D Inspection System.

“Innovation is an idea in action” was the motto under which the company celebrated its anniversary

Today, more than 20 years later, the company can look back with pride on its global leadership position in the use of block-height measuring systems.

R&W Industrieautomation, however, still has many other exciting ideas in the pipeline whose implementation is planned in the coming years. The company would like to take this opportunity to thank all its highly committed staff, as well as its loyal customers, reliable suppliers and valuable partners that have accompanied it on its exciting journey. Their trust and support are the key to company success.

“The future looks promising since the team at R&W Industrieautomation is determined to continue to develop innovative solutions and to push its vision. We are excitedly looking forward to see what the next 25 years will bring for this dynamic company,” concludes Uwe Rahn.

CONTACT

R&W Industrieautomation GmbH

Weidenstr. 1

57627 Hachenburg/Germany

+49 (0)2662 94 14 34