Automated quality control on a new level

Since 2001, R&W has been offering a high-performance block height measuring system with the SHV500 that had been conceived for the demanding conditions in modern concrete block factories specifically. According to the supplier‘s information, leading manufacturers across the world rely on the system – who are convinced of its exceptional measuring accuracy, user-friendly handling and long-lasting ruggedness.

A special feature of the SHV500 is its modular set-up, which, in combination with its universal compatibility to all common concrete block making machines, allows an uncomplicated integration into existing production processes. R&W draws on experiences gained in the industry over decades and has profound know-how in the development of highly precise measuring systems for concrete blocks.

Experience meets innovation

For four years now, R&W has been supplying with the 3D Inspection system a consistent further development of the well-established SHV200 and SHV500 devices. It provides comprehensive height measurement, detailed surface analysis and intelligent process monitoring, supplemented by board weighing and RFID tracking, upon request. Existing SHV500 block height measuring systems can be upgraded to become a 3D Inspection system. R&W offers extensive support for all systems, from commissioning through to the ERP integration and this all over the world.

R&W 3D Inspection system

With the 3D Inspection system, R&W sets new standards in the field of automated quality control in concrete block manufacturing – both in terms of technology and in view of integration depth and applicability in the real production environment.

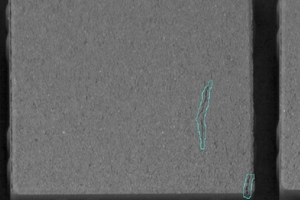

The patented system combines state-of-the-art 2D and 3D sensor technology with AI-supported fault analysis. It can be fully integrated into the machine control system, allowing for an automated adjustment of the inspection parameters when changing the recipe or mold. The production process is stopped automatically in case of imperfect production batches, which contributes to an early fault prevention.

The 3D Inspection system enables fully automated quality control in real time on the wet side of the production directly, or even on the dry side, as an option. Using state-of-the-art image processing and AI technology, the system recognizes even finest surface cracks, detachments or spalling and is exactly measuring the height of each individual concrete block in a range of up to 700 mm.

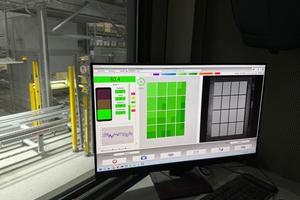

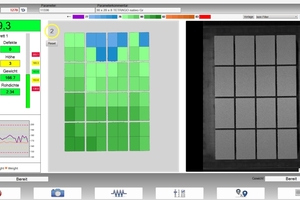

Production reliability through visualization and real-time reaction

Defects such as cracks, spalling, holes or detachments are detected with a high level of reliability, independent of the color of the concrete blocks. A user-friendly visualization indicates deviations in real time, providing the operators with immediate feedbacks.

All measured values are recorded in a data base and can be easily evaluated in the R&W software. Product-specific tolerance limits can be recorded in the software and stored in the recipes.

Monitoring of color gradient and color consistency

Consistent color shades are important in the production of concrete blocks so as to avoid later complaints by the customers. The automated color analysis of the 3D Inspection system enables the operator of the concrete block making machine to detect deviations from the requested color gradient owing to inconsistent concrete mixtures in real time. The requested colors can be taught in the system for specific products and stored in the recipe parameters.

This is possible for concrete blocks with single-colored as well as multi-colored surfaces. In this regard, the individual color components, their frequency and size are monitored by means of limit values. Hence, irregularities in the color gradient can be detected in good time, for making adjustments in the mixing ratio.

Apart from the block height, the weight is one of the key features for the quality of freshly produced concrete blocks. For reliable recording, the weighing system of R&W can be installed directly downstream the block height measuring system.

Board weighing: Precise control of weight and density for concrete blocks of high quality

The conveyor positions the board with concrete blocks onto a rack equipped with load cells. The dead weight of the board can either be entered into the SHV-Visu software manually or read out automatically through an RFID chip integrated in the board. The control system of the plant determines the overall weight of board and concrete, using it to calculate the exact concrete weight by subtraction.

This weight determination in collaboration with the volume measurement of the concrete blocks is the basis for continuous monitoring of the bulk density, an essential parameter for ensuring the material quality and a constant process in the production of concrete blocks.

Product tracking for automated sorting included

Another advantage of the R&W systems is the seamless product tracking of the production data along the wet and dry side by RFID transponders. Production boards that can be identified are used to ensure a closed flow of information from the wet side to the dry side. An RFID chip inserted in the production board is the basis of the technology; it allows a clear identification of the board along its way through the production process.

The combination with an R&W block height measurement allows a continuous quality management, because for every block layer all data are available and traceable up to packaging. Variations in quality are immediately indicated on the dry side.

R&W at Bauma 2025 – highest precision meets fastest data evaluation

According to their own information, on the occasion of this year‘s Bauma 2025, R&W has proven with the SHV-3D Inspection system once again, why the company is regarded as specialist for measuring and quality control systems in the concrete block industry. In particular, the combination of fastest data evaluation and highest precision excited the professional visitors as well as the regular customers all along the line. In practice this means: immediate analysis, direct fault indication and maximum reaction speed in real time.

Conclusion

The R&W 3D Inspection system combines long-term experience gained in industry and in the sector with state-of-the-art sensor technology, AI technology and sophisticated process integration. The system allows an efficient, automated and interconnected quality control, that can be smoothly integrated into existing production processes.

CONTACT

R&W Industrieautomation GmbH

Weidenstr. 1

57627 Hachenburg/Germany

+49 (0)2662 94 14 34