Peri Pave ReLife to make UK debut at MPA Precast and Masonry Expo 2025

15.05.2025

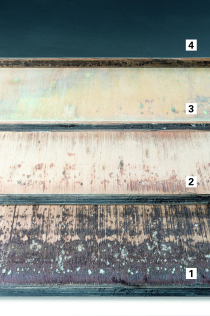

Figure: Peri UK

Peri UK, in collaboration with its UK agent Procter Johnson, will be exhibiting at this year’s MPA Precast and Masonry Expo, taking place 15th May at the Welford Road Stadium in Leicester. The event will serve as a platform for the UK debut of Peri Pave ReLife – a new refurbishment service designed to extend the life of Peri Pave production pallets by an additional 5-7 years, reducing waste and improving sustainability in brick, paving, and concrete block manufacturing.

Figure: Peri UK

Peri UK, in collaboration with its UK agent Procter Johnson, will be exhibiting at this year’s MPA Precast and Masonry Expo, taking place 15th May at the Welford Road Stadium in Leicester. The event will serve as a platform for the UK debut of Peri Pave ReLife – a new refurbishment service designed to extend the life of Peri Pave production pallets by an additional 5-7 years, reducing waste and improving sustainability in brick, paving, and concrete block manufacturing.

Now launching in the UK

Visitors to the show will also be able to explore Peri Pave , the long-established high-performance production pallet. The latest generation has been updated to feature a plastic coating with an integrated release effect, significantly reducing the buildup of concrete and stone residues. This means less cleaning effort and greater efficiency on the production line.

With its uniform vibration performance, excellent flatness, and low self-weight, Peri Pave is ideal for manufacturing heavy or precision concrete components. These benefits along with its long-lasting construction – typically offering a service life of 10-12 years – make it a reliable and sustainable choice for manufacturers seeking long-term performance, quality and faster cycle times.

Peri Pave ReLife, introduced earlier this year at bauma 2025 and now launching in the UK, builds on this legacy by offering a professional service to refurbish and recoat existing Peri Pave production pallets. By restoring their surface and structural properties, ReLife provides a cost-effective, environmentally conscious alternative to replacement.

Quality and longevity

Attendees at the MPA Precast and Masonry Expo are invited to visit the Peri and Procter Johnson stand to explore these products firsthand and speak with technical experts about optimising their production processes.

Peter Clifton, Peri Pave Manager at Peri UK commented: “When paving and precast concrete manufacturers choose Peri Pave, they are investing in quality and longevity. This is very important, especially when manufacturing products like this on a large scale, as it ensures consistency. We’re also excited to show how we can extend the value of our product pallets further through maintenance and care with Peri Pave ReLife, reducing both costs and environmental impact.”

CONTACT

Peri UK

Brentwood Office and Depot

Warley Street, Brentwood

Essex CM13 3JZ/United Kingdom