Peri Pave fact check: Why the production board is a global success

Wooden production boards are often criticized in concrete block production: too sensitive, too short-lived, too maintenance-intensive. Peri addresses these preconceptions with a fact check – and shows why Peri Pave has been valued worldwide for 25 years.

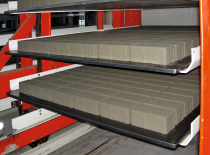

For decades, Peri has been a leading supplier of formwork and scaffolding systems, as well as wood-based materials, impressing customers with its quality, innovation and customer focus. With Peri Pave, the company has developed a production board especially optimized for concrete block production – a product that is by now used in more than 35 countries.

Kathrin Wunder and Martin Manz, Sales and Product Managers at Peri Pave, explain why the board not only meets the requirements of industry, but also sets new standards in many areas,FgluedFglue based on specific properties and practical experience. A new sales strategy also shows how Peri intends to remain a strong partner for production boards in the future.

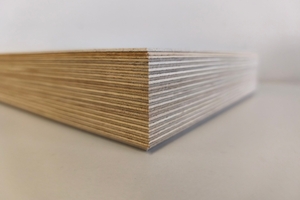

Fact 1: Stability begins at the core – the structure behind Peri Pave

Peri Pave is more than a classic plywood board, because its high-quality multiplex construction has been especially tailored to the requirements of concrete block production. Unlike plywood, however, very thin, evenly peeled veneers are used here, glued crosswise in several layers to create a special load-bearing structure. This manufacturing process ensures high dimensional stability even under changing climatic conditions – while keeping the weight low.

Fact 2: Moisture? Peri Pave shows its edge

Wood and water – a difficult relationship? Not for Peri Pave, because the edges of the board are designed to be open to diffusion. This allows moisture to be absorbed and controlled in a released manner – a decisive advantage in production environments in often very humid production environments. This controlled moisture exchange, in conjunction with the design of the production board, prevents the board from swelling and cracking, or the coating from flaking off. At the same time, an especially developed edge varnish reliably protects the wood from uncontrolled water ingress – even with high humidity or extreme conditions in curing chambers.

“What many assume to be the weakness of our product is actually our real strength: we make use of the natural properties of wood by intentionally allowing low absorption and release of moisture – controlled and in harmony with the natural properties of the raw wood material. In this way, our product specifically addresses the challenges in the production process,” explains Kathrin Wunder.

Fact 3: Smart coating minimizes the need for release agents

The abrasion-resistant special coating ensures that the blocks have clean rear sides and also minimizes the use of release agents, thanks to its special separating effect. “The majority of our customers work entirely without release agents, which not only protects the environment but also reduces operating costs,” says Kathrin Wunder.

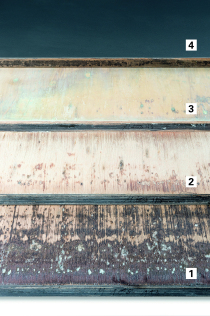

Fact 4: Durable and sustainable thanks to ReLife recoating

Compared to inexpensive softwood boards, Peri Pave scores with a significantly longer service life and an optimized production process. This improves the overall balance sheet in the long term. Optimal and uniform vibration transmission significantly reduces vibration energy and operating time and keeps it at a low level over the long term. At the same time, our customers benefit from the consistently high quality of their end products.

In addition, Peri Pave is impressive with its significantly reduced maintenance requirements, which lessens the risk of prolonged downtime and thus saves both time and money. Disruptions are eliminated in the production process: e.g., splitting, warping, swelling and the resulting jamming in the cycle. Although the resulting secondary costs are often not taken into account in investment decisions, they do have decisive economic significance over the years. With ReLife Service, Peri moreover offers the possibility of recoating used boards and of thus markedly prolonging their service life. Martin Manz regards this service as a logical response to the question regarding the sustainability of Peri Pave. “Our product has deserved to be extended – an absolute benefit both in terms of ecology and economy.”

Fact 5: A board with a future

The development of Peri Pave is based on in-depth expertise in wood processing and concrete production. This combination has resulted in a product that has proven itself worldwide under tough everyday production conditions. Peri will continue to focus on quality, sustainability and innovation in the future, and to pursue its goal of establishing Peri Pave even more broadly on the market.

“Peri Pave is the result of decades of experience and consistent further development. The satisfaction and loyalty of our customers motivate us every day to become even better,” says Kathrin Wunder, who has been jointly responsible for Peri Pave since 2005.

To ensure that the success story of Peri Pave continues in the future, Peri is focusing on even broader sales orientation. By tapping into new markets, its goals are exploiting previously untapped potential and, at the same time, more sharply bringing into focus the added value of Peri Pave. Martin Manz explains: “We can and want to do even more. Peri Pave meets the highest standards of quality, cost-effectiveness and sustainability. Our goal is to make the resulting success and advantages accessible to even more customers.”

Fact 6: Close to customers worldwide

In its global market development, Peri relies increasingly on local partners with industry experience. Through close contact with local experts, Peri Pave aims to gradually tap new markets, respond specifically to changes within those markets, and thus make the board and its advantages accessible to even more customers. This creates a particularly close connection with the customer.

“We invest in proximity and visibility: with a clear focus on the needs of our customers and support by experienced new sales partners from industry, we create proximity, trust and genuine added value,” emphasizes Manz.

A success story with perspectives

Together with Peri Pave, the company can look back not only on 25 successful years – but above all can look ahead. Quality, sustainability, and innovative strength will continue to be the guiding principles for a product that is more than just a board: from a reliable partner for the requirements of today and tomorrow.

CONTACT

Peri GmbH

Schalung Gerüst Engineering

Rudolf-Diesel-Straße 19

89264 Weißenhorn/Germany

+49 7309 950-0