Turkish association delegation visiting the new Wöhrl facility

Wöhrl Ziegelwerk-Deckensysteme GmbH, an owner-managed company in the fifth generation, has been manufacturing precast floor slabs of the highest quality at the Wolfersdorf site for more than 50 years now. Since the existing plant has been getting on in years, the idea for installing a new plant at the new Zolling location was developed. Prilhofer Consulting was assigned with planning the new plant. The concept of the new highly automated factory in accordance with state-of-the-art technology is now providing the possibility to produce double walls too. This product has gained more and more importance and, what is more, a delivery of all precast products from a single source often becomes a critical factor in purchasing decisions for the clients/building owners.

Following an earlier extensive plant modernization with a high-performance planetary mixer of Teka Maschinenbau (see report in BFT 10/2018), among others, Wöhrl now took another decisive step towards the future.

At the end of 2020, planning commenced and the layout as well as the concept for the production plant of Wöhrl was finalized just after a few months. Now, in the course of the permission and funding procedures, a lengthy steeplechase began through the German red tape. Progress Group succeeded in the tendering process regarding the plant equipment and could secure the contract for the equipment of the new plant. At the beginning of 2024, construction and installation of the new plant could start and concrete could be placed on the first pallets in mid-March of 2025. The production of the first double wall marked a big event in the company history at Wöhrl. With the relocation of the complete production to the new facility at the end of April 2025, Wöhrl has accomplished a huge milestone in the more than 160-year company history.

Brief description of the new plant equipment

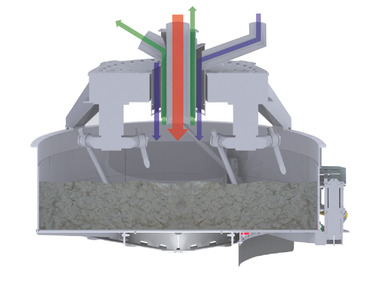

The new plant was errected in Zolling near Munich with the participation across the company group ranging from Ebawe Anlagentechnik GmbH, Progress Maschinen & Automation AG and Progress Software Development GmbH. An ultra-modern pallet carousel system was supplied for the production of precast floor slabs, double walls and solid walls, being equipped with integrated reinforcement machines, as well including the latest software solutions of the Progress Group.

The scope of supply comprised 48 pallets, a pallet cleaning device with rubble conveyor, four laser projection systems, a FormMaster storage and shuttering robot each, Econ Drive concrete spreaders, vibration device, roughening unit, pallet stacker with curing rack, turning equipment, tilting equipment, run-off carriage, scissor-type lifting beam, M-System BlueMesh mesh welding line, magnetic traverse for inserting of the mesh, Versa lattice girder welding machine as well as Ebos, Erpbos and BIMpro systems.

A comprehensive report on the new plant equipment at Wöhrl from the perspective of the Progress Group will appear in one of the forthcoming BFT issues.

Turkish association delegation paid a visit

On the occasion of bauma, a delegation of the Turkish membership association of BIBM took the opportunity to get an idea of the new facility in the vicinity of Munich. This visit took place on the initiative of Alessio Rimoldi (General Secretary of BIBM) and Diana Krüger (Technik & Betrieb FG Betonbauteile im Bayerischen Industrieverband Baustoffe, Steine und Erden e. V.) of the Bavarian building materials industry association.

CONTACT

Wöhrl Ziegelwerk-Deckensysteme GmbH

Berghaselbach 5

85395 Wolfersdorf/Germany

+49 8168 9062-0

Progress Group

Julius-Durst-Strasse 100

39042 Brixen/Italy

+39 0472 979900

info@progress.group

Prilhofer Consulting GmbH & Co. KG

Münchner Str. 1

83395 Freilassing/Germany

+49 8654 6908-0