The correct use of concrete release agents in the construction industry

Architectural concrete is enjoying increasing popularity in the architectural design of buildings. Concrete release agents are available for this purpose, which, in addition to ordinary formwork stripping, enable the creation of visually high-quality concrete surfaces. This article explains the function, types, application and significance of concrete release agents.

Concrete is a fundamental building material in the construction industry, and its ease of processing, as well as its strength, durability, versatility and individual designs make it an indispensable part of modern construction. In the manufacture of concrete products, it is crucial that the products can be easily removed from the molds, without causing damage such as spalling, shrinkage holes and broken corners that require costly repairs. At the same time, architectural concrete is generally enjoying increasing popularity in the design of buildings.

Practical realization of the desired appearance of a concrete surface is crucial to the objectives of the planning designer. As a result, demands for visually high-quality concrete surfaces are continuously increasing. This is where concrete release agents come into play: they enable the concrete to be stripped easily and, at the same time, play a crucial role in achieving visually high-quality concrete surfaces. This article explains the function, types, application and significance of concrete release agents in the construction industry.

Function and significance of concrete release agents

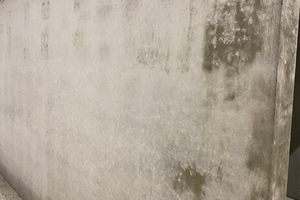

Concrete release agents are substances that are applied to the surfaces of formwork to enable simple and clean stripping of the concrete. Their main function is to reduce the adhesion between concrete and formwork. This not only contributes to enhancing the surface quality of the concrete, but also considerably facilitates the stripping process. Correct use of concrete release agents can increase productivity and prolong the service life of the formwork – which, again, leads to cost savings. When correctly used, moreover, they contribute to the visual appearance of the concrete surfaces (Fig. 1).

Types of concrete release agents

Various types of concrete release agents are available. The most important are oil-based, water-based and wax-based formulations. Oil-based release agents provide outstanding separation and are well-suited for use with complex formwork. Water-based release agents are environmentally friendlier and easier to handle, whereas wax-based release agents have good separation properties and provide additional protection.

Uses and types of application

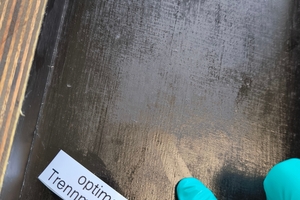

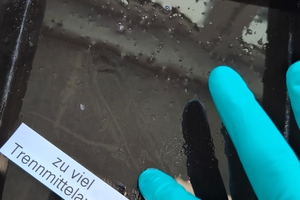

Application of the concrete release agent to be used depends on matching its particular type to the specific requirements of the construction project. One crucial parameter is the thickness of the release agent film: see Table 1 and Fig. 2. In order to obtain a very thin film, the quantity must be applied as recommended. This is realized with a well-coordinated combination of product viscosity and choice of application. For steel formwork, a release agent with corrosion protection is recommended. In addition, the ambient temperature and the temperature of the release agent must be considered. The lower the temperature, the longer the time required for formation of the film. The temperature of the product should also not be too low for achieving a uniform appearance.

To ensure obtaining an optimal release film, the release agent is in most cases applied by spraying it onto the formwork surface. This method is primarily used for water-based release agents. The release agent is uniformly applied to the surface of a mold or formwork with the aid of such devices as a spray system, a high-pressure spraying device or a spray unit with a rotation nozzle. Spraying enables uniform distribution of the release agent, which leads to effective separation. In addition, it is possible to apply a thin film of the release agent to the surface by means of a suitable mop.

Important steps for applying the release agent are:

1. Thorough cleaning of the formwork (the surface should be dust-free);

2. Installation of embedded parts, reinforcement excluded;

3. Application of the release agent and paying attention to the type of nozzle and pressure (min. 4 bar;

4. Uniform misting of the release agent is sufficient – any excess application can be wiped off with a clean cloth;

5. Ensuring that the oiled surface is not stepped on;

6. Ensuring that the concrete is correctly installed.

Cleaning of formwork

Cleaning the pallets on carousel systems is important and greatly influences the quality of the final concrete surface. To simplify this step, and to lower the costs of time-consuming cleaning, Master Builders Solutions has developed the CLN 689 MasterFinish Formwork Cleaner. MasterFinish removes concrete residue, rust and paint and cleans the brushes of the formwork cleaning stations (Fig. 3). For this purpose, the cleaner is sprayed either directly onto the formwork – or, a spraying system is installed at the cleaning station that sprays the required amount onto the cleaning brushes. At the end of the pallet, a levelling blade is installed which removes any excess from the cleaner.

In this manner, both the brushes and the pallet can be thoroughly cleaned (Fig. 4). This not only significantly reduces the wear on the brushes, but also continuously improves the cleaning capability of the brush.

Successful application

In order to obtain an optimal stripping result, preliminary tests and adjustment of the plant systems are often unavoidable. The experienced experts of Master Builders Solutions, a leading supplier of concrete release agents and other release agents, will be pleased to support potential users.

CONTACT

Master Builders Solutions Deutschland GmbH

Glücksteinallee 43-45

68163 Mannheim/Germany

oliver.mazanec@masterbuilders.com

www.master-builders-solutions.com/de-de/produkte/masterfinish/