Thailand’s leader in the construction sector modernizes building solutions with automated hollow-core production lines

Pruksa Real Estate Public Company Limited, the well-known real estate development market leader in Thailand, modernized two of its existing precast plants to include the production of hollow-core slabs with a high level of automation using machinery from Echo Precast Engineering, a Progress Group company. Pruksa introduced precast technology as the first company in Thailand and continues to develop this advanced and innovative technology there. With the latest investment in the hollow-core production line, Pruksa continues to implement automated processes to improve productivity and efficiency while significantly reducing human error rates.

First green factory in Thailand

The market leader developed the first green factory in Thailand, which works on the basis of strict sustainability development policies for waste as well as noise pollution in the factory. A distinction has been made between three aspects of operation: the Heart to Home, the Heart to Earth, and the Heart to Society.

Sustainable production for sustainable living conditions

Particularly in the current situation, the focus is even more on creating a new standard of living. Pruksa states: “We see megatrends that affect the housing of people all over the world: health and wellness is being redefined, and real estate developers need to create a new definition of comprehensive healthcare offerings to residents. Lifestyle disruption was immense, so we need to create a new way of life which is adaptable to changes by leveraging ground-breaking innovations to enhance living conditions.” Also, to ensure sustainability of the environmental, social and living perspectives, Pruksa has been innovating the real estate market in Thailand for almost 30 years. Pruksa Real Estate was founded by Thongma Vijitpongpun and focuses on developing projects for townhouses, single-detached houses and condominiums with the mission of developing high-quality housing at reasonable prices and thus ensuring better living conditions. 1,600 people work for the company and help with innovating the construction sector by a wide range of state-of-the-art approaches, combining the environmentally friendly design with appropriate resource allocation in every process.

Precast concrete plants – a crucial factor for sustainable construction

Pruksa invested in its first precast plant as early as 2005. Since its establishment, the company has been firmly convinced that the focus needs to be on innovation, and has lived this vision also through the system of building with prefabricated concrete elements. In the beginning, Pruksa concentrated on delivering town houses using tunnel form construction. As the company grew and wanted to meet the requirements and demands as well as gaining more market share in the single-detached house segment, it applied new methods by using innovative precast systems. The equipment for the automated carousel plants was provided by Ebawe Anlagentechnik and Progress Maschinen & Automation, the software solutions came from Progress Software Development, and the new hollow-core production lines were supplied and installed by Echo Precast Engineering – all of them are members of Progress Group. The main products made in the plants are walls and slabs for the fast and secure construction of residential housing.

Hollow-core slabs complement automated production

The decision to renew the two factories was made just a few years ago in order to develop hollow-core production. Pruksa operates seven sites; PCF3 and PCF7 were the factories that originally supplied solid slabs. The company did a lot of research on hollow-core slabs and got convinced of the benefits of such elements. Hollow-core slabs are efficient in design, production, and construction. They contribute to the sustainability concept as well because they reduce the amount of concrete needed and thus the weight of the slabs. Building upon this knowledge, Pruksa decided to modify the slabs for their house designs and converted PCF3 and PCF7 into two highly automated hollow-core production plants equipped with machinery from Echo Precast Engineering to supply all their building projects.

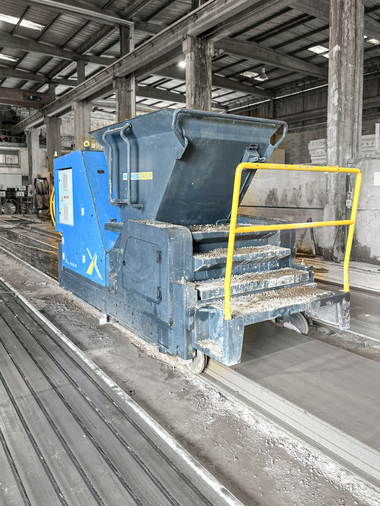

The new hollow-core production lines are equipped with a 2.4 m S-Liner universal slipformer to produce two rows of 1.2 m wide slabs but can be flexibly adjusted to produce one 1.2 m as well as two 0.6 m slabs at the same time. Additionally, a multi-functional, battery-driven trolley, which is also 2.4 m wide, supports the production process. The installed concrete aspirator makes accurate cut-outs, openings, and protruding reinforcement in hollow-core slabs in an effortless process. In addition, an automatic SmartJet plotter featuring the advanced line detection technology of Echo Precast Engineering was supplied together with an MAS multi-angle saw in the 2.4 m wide design. Additional equipment includes the systems for lifting 1.2 m and 0.6 m wide slabs. This machinery helps not only with the faster and safer production of hollow-core slabs but also makes a major contribution to the green factory concept since concrete consumption is reduced by 40% compared to solid slabs, thus facilitating a green and sustainable production setup.

“The decision in favor of Echo Precast Engineering was made not only due to the high quality of the machinery and technology but also as a result of the good coordination and machine design that met our requirements”, says Porntep Suppataratarn, Group Chief Procurement and Supply Chain Officer, and adds: “We did not only want to implement the hollow-core system but also intended to increase the level of automation in the storage location system, and thus needed the systems to synchronize. So, with Echo we contracted a supplier from the same group as the supplier of the existing factory and storage location systems.” He was also happy to say that the project worked out well even in these challenging times and circumstances thanks to the above-mentioned good coordination: “The collaboration was very impressive”, he concluded.

CONTACT

Pruksa Real Estate Public Company Limited

No. 1177, 23rd Floor, Pearl Bangkok Building

Phahonyothin Road, Phayathai

Bangkok 10400/Thailand

+66 2 080 1739

Echo Precast Engineering NV

Industrieterrein Centr. Zuid 1533

3530 Houthalen/Belgium

+32 11 600 800

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979159

EBAWE Anlagentechnik GmbH

Dübener Landstraße 58

04838 Eilenburg/Germany

+49 3423 6650

Progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+ 39 0472 979100