Sustainable modernization: E. Victor Meyer relies on new technology in hollow core production

With its sustainable technology and strategic investments, E. Victor Meyer demonstrates how innovation and efficiency can go hand in hand in the construction sector. The use of state-of-the-art machines from Echo Precast Engineering, a company of the Progress Group, strengthens the Meyer market position, while at the same time reducing its CO2 footprint – a model for the entire industrial sector.

The company E. Victor Meyer in Belgium, founded in 1980 originally as a transport carrier, has developed into a major player in the construction sector. Following extension of its business areas – progressing from crushing and sieving stone to production of prestressed concrete products – the company pursues a clear strategy: modernization through innovative technologies.

Strategic investments in efficiency and sustainability

In view of rising cement prices and increasingly stricter requirements to ensure CO2 reduction, E. Victor Meyer has invested in comprehensive modernization of the company’s production facilities. The goal was to make processes more efficient, more cost-effective and more environmentally friendly. Toward this goal, the company chose the technology used by Echo: including the S-Liner T30 slipformer, an automatic SmartJet plotter and a concrete aspirator.

S-Liner T30 slipformer: sustainability and speed

The switch to the slipformer technology was a milestone: by use of zero-slump concrete, cement consumption could be reduced by up to 20 %, resulting in significantly improving the CO₂ balance. In addition, hardening time decreased from 24 to 16 hours – an increase in efficiency of 30 %.

SmartJet plotter: precise and digital

The automatic SmartJet plotter optimizes production by precise marking, integrated drilling of drainage holes and paperless documentation. The result: higher product quality and less waste with a reduced workload.

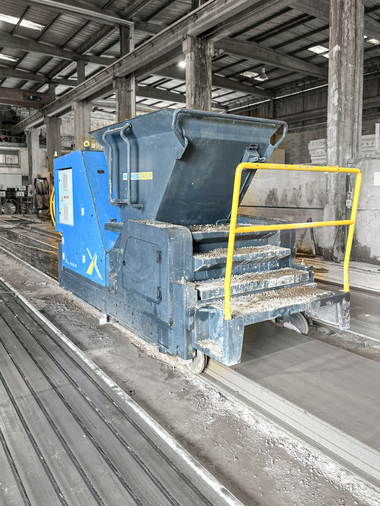

Concrete Aspirator: focus on ergonomics

Complex elements with numerous openings can be manufactured faster and more ergonomically with a concrete Aspirator. Its use provides all participants in the process with considerable physical relief.

“Reduction in the amount of cement was the major goal for modernization. Improved hardening of the products was also important. Where we used to need 24 hours without heating and now we need only 16 hours. We are reaching the needed strenght much faster and this with a cement saving of 25%,” says Raymond Palm, Co-Administrator at E. Victor Meyer.

Current market trends as driving force

Modernization enables E. Victor Meyer not only cost savings, but also compliance with future environmental standards – a crucial advantage in an industrial sector that increasingly focuses on sustainability. At the same time, the company has responded to the trend for prestressed concrete elements, demand for which has especially increased for floor elements. In order to achieve this development, E. Victor Meyer took over another company that already manufactured prestressed concrete, which strategically extended the Victor portfolio.

“The fact that Echo is located only an hour away and that we already had been collaborating with this company for many years, was of strategic advantage here. Echo supported us with expert knowledge and reliability in our project: beginning with consultation and extending to installation of the new machines,” says Raymond Palm.

A major step into the future

By investing in modern machines, E. Victor Meyer sets standards for innovative strength and sustainability. The modern technologies not only ensure competitiveness but strengthen the position of the company as a future-oriented market leader in precast element production.

CONTACT

E. Victor-Meyer

Av. de Norvège,

454960 Malmedy/Belgium

+32 80 33 71 93

Echo Precast Engineering NV

Industrieterrein Centr. Zuid 1533

3530 Houthalen/Belgium

+32 11 600 800