Successful collaboration: Kniele and Simotec rely on state-of-the-art mixing technology

It will be official from mid-August 2025: Kniele Mischtechnik is entering into a strategic partnership with Danish plant manufacturer Simotec. Both medium-sized companies have already successfully implemented projects in the past – now the next logical step follows: deeper cooperation with a focus on the Scandinavian market. This new partnership is a strong signal for greater efficiency, quality, and innovation in plant engineering and mixing technology.

The aim of the partnership is to pool the expertise of both companies in a targeted manner. The focus is particularly on mixing systems and the Kniele KKM cone mixer – a highly efficient solution for precise and homogeneous mixing of a wide variety of materials.

Simotect contributes its extensive experience in plant engineering and the planning of industrial manufacturing processes. In close cooperation, the possibilities for integrating the high-performance Kniele products into future plant solutions are being explored.

Exciting project with Kniele KKM375/550 cone mixer

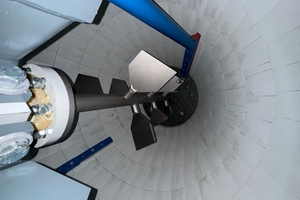

Kniele GmbH has successfully implemented an exciting project in collaboration with Simotec S/A. At the heart of the project is the Kniele KKM375/550 cone mixer, equipped with a standard outlet, ceramic lining, and a high-pressure cleaning system. The system was supplemented with customized components from Simotec, resulting in a powerful and future-proof overall system.

The cone mixer impressed with its proven Kniele technology. For this project, it was equipped with:

Standard outlet with concrete chute (added later)

Ceramic lining for durability

High-pressure cleaning system for efficient cleaning.

This means it is optimally equipped to meet the highest production requirements.

Simotec as a reliable partner

In addition to the mixer itself, Simotec played a central role. Among other things, the company supplied:

Mixer platform including railings and stairs

Measuring cells for the mixer

Cement scale and mixer dust extraction

Complete control system with Siemens PLC, including control cabinet

Manual weighing device (e.g., for fibers or color), including documentation in the recipe.

Simotec also took care of the pre-assembly of the entire mixing plant - including the Kniele mixer - at the site in Denmark. The project kicked off at the end of 2022 with an initial exchange via MS Teams video conference.

Collaboration on equal terms

From there, the project proceeded in close coordination:

Exchange of 3D CAD models and initial designs

Clarification of the required electrical components (e.g., motor power, limit switches, measuring transducers)

Preparation of the offer by Simotec

After the order was placed, close exchange about interfaces – both in terms of design and control technology

Regular project meetings in which complications were resolved and design standards were defined.

After completion, the final acceptance was carried out by Kniele directly at Simotec. The final commissioning of the system was successfully carried out in March 2024.

Conclusion: A successful project with added value

The cooperation between Kniele GmbH and Simotec shows what successful collaboration looks like in practice. The intensive exchange of information, the clear definition of interfaces, and the joint solution expertise resulted in a state-of-the-art mixing plant that meets the highest standards.