Modernization of both Westerwelle production sites with mixing technology from Kniele

W. Westerwelle GmbH + Co. KG, a manufacturer of L-shaped concrete retaining wall panels in different sizes and designs, concrete steps and non-standard concrete components, successfully modernized its two production facilities in Herford, Westphalia, and Beeskow, Brandenburg, within just a few years.

Now in its third generation as a family-run business, Westerwelle stands for reliability, economical prices and short delivery times. As a partner to the building materials trade, the company always complies with the requirements of engineering construction. Numerous aspects in the production of concrete components have been continuously improved, optimized and standardized over the years. Formulations, designs, surfaces, colors, structures, connection systems, equipment features and production processes are governed by the company’s own high quality standards, as are the services offered, because all products are branded items.

When Wilhelm Westerwelle founded the company together with his wife, Hilde, in 1955, the foundations were laid with products such as curbstones, slabs and paving blocks. Manfred and Cornelia Westerwelle set new standards in the areas of quality, marketing and sales when taking over the company in 1985. In 2005, Westerwelle opened a sales office for Eastern European customers in Wroclaw, Poland, and when the demand for concrete components from Westerwelle increased many times over, the decision was made in summer 2008 to set up an additional production site in the town of Beeskow, Brandenburg.

Kai-Uwe Westerwelle has been at the helm of the long-established company since 2010. Two collection warehouses have since been established – P&A Store in Lehrte in 2014, and Woehe & Heydemann in Kummerfeld in 2019 – to give customers throughout Germany even easier access to the company’s range of L-shaped retaining wall panels. An additional location was set up in Mragowo, Poland, in 2019, which enables Westerwelle to expand its international sales.

Managing director Kai-Uwe Westerwelle explains: “Our customizable technical solutions are what set us apart. We offer more than standard quality and a wide range of products: from L-shaped retaining wall panels in different sizes and designs to steps and non-standard components with a surprisingly wide range of applications. We are always on hand to advise our customers and partners, whether in planning, structural analysis or general matters. Always responding to requests for quotations within 48 hours, we offer a service that our customers have long appreciated.”

Westerwelle currently employs a staff of around 120; in addition to the facilities in Herford and Beeskow, the company operates the previously mentioned sales office in Wroclaw and a production facility in Masuria (both in Poland). The company also has its own in-house reinforcement construction.

Extensive modernization at the main plant in Herford

The first steps were a design contract and 3D scan. The inline silo with feeder was in place; the new dosing valves and dosing chutes were supplied by Kniele. The weighing belt was fitted with new load cells, and a new feed elevator with fall protection was installed. A new mixer platform was also supplied by Kniele after the old one had been dismantled.

The actual heart of the system is the new Kniele KKM 1500/2250 cone mixer with ceramic lining and Widia screw, moisture and temperature sensor. It is complemented by a new weighing platform with cement-weighing unit, water weighing unit, admixture weighing unit and liquid-paint dosing system (both supplied by Würschum), as well as a forced mixer dust extraction system and mixer camera. The cement silos were already in place, the control and power unit was supplied by Bikotronic, and the new cement screws were supplied by WAM.

New Kniele plant also for the Beeskow facility

A new Kniele mixing plant was put into operation at the Westerwelle facility in Beeskow a little earlier, in November 2023. This plant impresses with a perfect combination of new construction and connection to the existing building units.

The origins of the Beeskow concrete plant date back to 1993, when a pipe and manhole production plant was set up on the same site. In 2005, Westerwelle set up a sales office for Eastern European customers in Poland, and the success proved it right. The continuously growing demand for the concrete components increased many times over, so that the decision was made in summer 2008 to set up a second Westerwelle production site in the town of Beeskow, Brandenburg. Concrete production started with existing equipment, accompanied by adjustments from zero-slump to moist/flowing concrete for filling the mold systems of the L-shaped retaining wall panels. Guido Poßin, current operations manager and a native of Brandenburg, has been involved in various positions almost from the very beginning.

Discussions and initial planning began in 2020/2021. To optimize the possibilities of production, the decision was made to replace the old mixer with the open aggregate bay system and dragline by a new mixer and weather-independent aggregate storage system. The goal was to ideally achieve a consistent aggregate level in order to guard against the hot summers in eastern Brandenburg and to also be flexible during the cold winter months.

Self-compacting concrete production at the highest level

Similar to the Herford plant, Kniele performed an advance 3D scan of the existing plant. The new concept was developed after various visits and numerous discussions: it begins with a concrete inline silo comprising four chambers for raw materials. The material is transferred to a mobile weighing unit via dosing valves, from where it is then conveyed upwards to the mixer in the feed elevator (with fall protection). A Kniele KKM 1500/2250 cone mixer with an output of 2,000 liters of hardened concrete, fitted with ceramic lining, Widia screw, moisture and temperature sensor, ensures an output of self-compacting concrete (SCC) in impeccable architectural concrete quality.

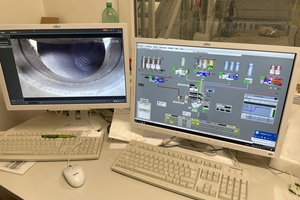

Bikotronic ensures smooth control of the plant. In-house concrete transport from the mixer to the mold systems is carried out by means of forklift trucks. Both the mixer control system and video monitoring of the mixer, dosing units and mobile weighing unit are therefore installed directly on the mixer and are always clearly visible. The weighing platform with dust extraction system, an admixture weighing unit from Würschum, the mixer camera, water weighing unit and cement weighing unit are installed on top of the mixing tower.

The new system produces self-compacting concrete for the precast concrete plant to the highest standards. The staff of around 30, headed by operations manager Guido Poßin, fills the L-shaped panel molds daily, using CEM II 53.5.

Residual concrete reclaimer from Ecofrog

In addition to modifying the mixing plant at Westerwelle, a residual concrete reclaimer was to be installed for the washing water resulting from cleaning the mixing plant and the buckets.

For this purpose, Ecofrog GmbH supplied an RE_X04Z residual concrete reclaimer with feeding wheel. A washing station for concrete buckets and small equipment was set up in front of the feeding wheel. Washing water from mixing plant cleaning is fed directly to the washing station via a downpipe. The washing water containing the concrete residue is fed into the reclaimer by means of the feeding wheel mounted on the reclaimer. Here the mixture is separated into: residual water (water containing ultrafines and cement) and washed-out mixed gravel. The gravel is discharged via an ascending vibratory chute and simultaneously drained via a built-in screen. The washed-out mixture of sand and gravel is available for reuse in concrete production.

The residual water flows into an agitator tank via an overflow outlet. In the agitator tank, the residual water is buffered and stirred at regular intervals to prevent settling of the ultrafines. A submersible pump installed in the agitator tank pumps the residual water to the water weighing unit of the mixing plant. This enables the full reuse of the washing water produced.

CONTACT

W. Westerwelle GmbH + Co. KG

Elverdisser Straße 205

32052 Herford/Germany

+49 52 21 97 55-0

Kniele GmbH

Gemeindebeunden 6

88422 Bad Buchau/Germany

+49 7582 9303-0