New mixing plant for fibre concrete factory Capremib

Last year, the French concrete manufacturer Capremib commissioned a new concrete plant at its site in Cormicy, northern France. Kniele GmbH designed the mixing plant under French representation BSC-BetonStoneConsulting especially for the production of fibre-reinforced concrete.

The new mixing plant brings Capremib to a new level. For quite some time, the desire was to establish Capremib as a player with fibre concrete. In the old plant in Cormicy, Capremib produced many conventional concretes – based on a variety of formulas. However, due to the high capacity utilisation, it was not possible to carry out extensive mixing tests with fibres.

In the middle of 2020, the construction of a new 250-m² production hall with the integrated new concrete mixing plant started. „The new plant is intended for the production of fibre-reinforced concrete,“ explains Clément Blanc, CEO of Capremib. „The new concrete plant is a technical powerhouse, which enables us also to test new recipes for special concretes and to produce small quantities.“

In the future, Capremib would also like to enter other markets, such as the production of refractory concretes. Thanks to the new cone mixer, this is also an option now.

In the French mega-project „Grand Paris“, fibre-reinforced concrete is preferred. For this reason, too, the course is being set in France towards a standard for the long-banned fibre-reinforced concrete.

Concrete mixing plant of

Kniele-BSC

The new concrete mixing plant is based on a Kniele conical mixer with a capacity of 1,500 litres. One of the special features of this mixer is that – thanks to its funnel shaped design and the special mixing tools – it can mix even small volumes of concrete (filling to 10 % of the nominal capacity), which is why it was chosen. The mixer is equipped with a high-pressure cleaning system for quick cleaning when changing colours or products - another major advantage of the KKM.

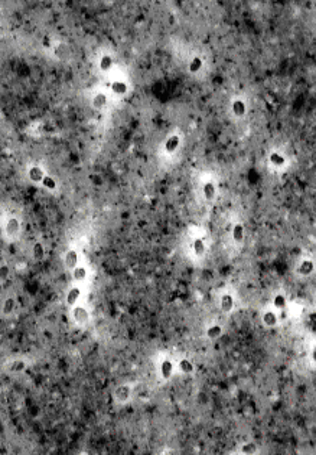

In view of its “UHPC” use, the plant includes two fibre feeders, to allow for multi-scale compositions. Due to the high fineness of the materials, the aggregate boxes have an ultra-precise dosing system. A mobile scale underneath the aggregate silos delivers the materials to the skip, which feeds the mixer. Two integrated big bag stations also allow the use of ready-to-use premixes; this ensures the versatility of the product range. Four different binders or powdery materials can be stored in two dual chamber cement silos that complement the plant.

BSI fibres from Eiffage

For the fibre-reinforced concrete, Capremib has chosen BSI fibres from the Eiffage Group. These are special synthetic fibres for ultra-high strength concretes. Nowadays, relatively few manufacturers can use this technology - but Eiffage has developed a wide range of solutions.

For the formulation of Capremib, Eiffage supplies the BSI fibres as a cement premix to which the other ingredients are added. Sand in various grain sizes, liquid admixtures and fibres. In addition to the UHPC, Capremib also produces various concretes with their proprietary formulation called Capremix.

The new concrete mixing plant from Kniele-BSC completes the main plant in Cormicy. For the expansion of the plant, an additional hall with around 400 m² was built. „This will be used exclusively for the production of fibre concrete,“ explains Clément Blanc. Just after the commissioning, Capremib produced the first prefabricated parts for the reconstruction of the Célestin-Philbois Bridge in Troyes. „This is probably one of the first bridges ever built in fibre-reinforced concrete. Subsequently, bridge slabs of grey fibre-reinforced concrete were produced for the Gerstheim Bridge on the border with Germany. With a thickness of 30cm, these allow a general brightening of certain elements of the overall structure.“