Saving an entire year of time with building system for nursing center

The residents of the St. Otto Bamberger Nursing Home will be able to move in an entire year earlier than originally planned. The Dennert building system of precast elements and completely outfitted bath modules proved to be a real building accelerator: work on the newbuild commenced in the autumn of 2024, topping-off was celebrated in February 2025. If conventionally constructed, completion would have taken about a year longer. The Ottoheim nursing center had no longer satisfied the specifications of the Bavarian Nursing and Residential Homes Quality Law in respect of the single-room quota and barrier freedom. In order to enable the residents to occupy the center during the construction phase, the project was divided into two sections. The first part was demolished from 2022 until the spring of 2024 and newly built – by conventional construction.

For the considerably larger second construction section, the precast element specialist Dennert, based in Schlüsselfeld in the Franconia region of Germany, was commissioned. Building took place as if in a time lapse film: in September 2024 Dennert began with the erection of the ground floor. The first floor followed already in October, four weeks later the second floor and the attic floor, by December the building was rainproof. Although demolishing of the old building had been delayed, interior finishing work could commence in January 2025, as scheduled.

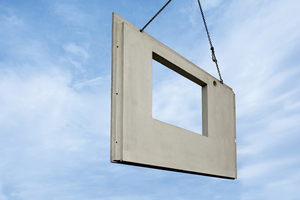

399 wall elements and 328 floor elements

A total of 399 wall element were installed on a floor area of 815 m² as well as 328 DX floor elements with an area of in total 2,500 m². The 78 windows, all of which were integrated in the walls, are also part of the delivery scope. In addition, there are two prefabricated staircase systems reaching from the ground floor to the second floor and the roof areas for the hipped roof and the flat roof.

Dennert delivered for the second section also the bathroom modules, 24 of which equipped for disabled use, complete with handicapped accessible shower, wheelchair-compatible washbasins and additional eight wheelchair-compatible WCs, fitted with supporting rails. The completely equipped and tiled bathroom modules must only be positioned on site, bolted together and connected to technical services – saving the use of many trades – and therewith time.

It is not only the time factor that speaks for prefabricated concrete construction for projects of this kind. Planning security in particular is an especially valuable factor. Work at the construction site is independent of the weather, neither freezing temperatures nor rain lead to delays. The construction material is to the major part already installed in the delivered elements, need not be stored on the construction site. Construction waste or debris of any kind from the construction process does not occur at the site. This reduces construction site traffic to a minimum which, in particular in inner cities, is a tremendous relief.

The St. Otto nursing center is expected to be completed at the beginning of 2026. The facility will then offer in its new, comfortable rooms a place for 105 residents and 16 daycare places.

CONTACT

Dennert Baustoffwelt GmbH & Co. KG

Veit-Dennert-Straße 7

96132 Schlüsselfeld/Germany

+49 9552 71-0