Hybrid construction in new dimensions

The hybrid construction method using wood and concrete is becoming more and more popular in property construction. Current projects show: This method is an effective answer to the shortage of skilled labor, rising costs and ecological requirements. The advantages are obvious: shorter construction periods, buildings of lower weight and an improved life cycle assessment. Thus, extra-light precast concrete floor slabs allow even realizing building heights economically and on schedule that had hardly been possible in mere wood construction so far.

Perfect match: The symbiosis of concrete and wood

The hybrid construction method combines load-bearing solid wood walls with precast concrete floor slabs especially developed by Dennert. Wood convinces with lightness, concrete with stability and a long service life.

A central advantage is the high construction pace: As a rule, a construction time of only five days is needed per story. The DX floor slabs prefabricated with high precision in an industrialized process feature an optimized vibration behavior, excellent sound protection and comply with fire resistance class F90. After assembly, the floors are immediately loadable and ready to walk on.

Prefabricated bathroom modules – Efficiency in the detail

Another core component of Dennert‘s system construction method, are industrially manufactured, fully equipped bathroom modules, which are delivered to the construction site ready for connection. This reduces construction times on site and simplifies logistical processes.

Shorter planning phase, better life cycle assessment

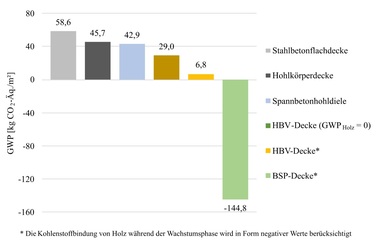

Standardization and serial production already shorten project planning substantially. In comparison to conventional reinforced concrete construction, carbon emissions can be reduces by up to 70 % depending on the overall concept. In the context of the scheme „Wohnpakt Bayern“ (Housing Pact Bavaria), an additional subsidy for sustainability was granted by the Free State of Bavaria for an eight-story apartment building in Fürth, the tallest hybrid building in Germany for the time being.

Example: Student dorm in Erlangen

How hybrid construction is convincing in practice is currently shown by the newly build student dorm in the city of Erlangen. Approximately 700 m² of Dennert concrete floors were used here as well as fully equipped bathroom modules in all 26 apartments. In this way, the construction period could be reduced by 30 %.

The neighborhood benefited too: The high degree of prefabrication meant less noise, less dirt, a substantially shorter construction phase and only minimal interferences owing to road closures.

Expertise in hybrid construction

With decades of experience in industrial prefabrication, Dennert provides the ideal basis for modern multi-story construction with their intelligent concrete floor slabs and modular solutions. The results are efficient, flexible and sustainable building concepts being in compliance with ESG, conservation of resources and future viability.

CONTACT

Veit Dennert KG

Veit-Dennert-Straße 7

96132 Schlüsselfeld/Germany

+49 9552 71-351