Residual concrete recycling system at Lithonplus in Gunzenhausen

Lithonplus is a subsidiary of Heidelberg Materials AG and Schwenk Zement GmbH & Co. KG and is one of the leading concrete product manufacturers in Germany. A team of 600 employees works at 18 locations across Germany.

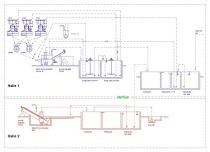

Lithonplus GmbH & Co. KG approached Bibko with a view to equipping its plant in Gunzenhausen with a recycling system. After thorough consultation and planning, the company opted for the RWS type washing machine.

The customer decided to lower the system into a pit, which has the advantage of reducing the feed height to one meter. Due to the conditions on site, this measure made it possible to include the system in the process. A 5 m long RWS spiral washer, into which the material is fed via a 1.5 m wide hopper, ensures ideal discharge of the washed material.

Since the residual concrete is emptied into the hopper from above via the concrete bucket conveyor, the hopper is equipped with splash guards.

Recycling capacity of 12 m³/h

The RWS 12 plant system supplied offers a recycling capacity of 12 m³/h and was delivered together with a 4 x 3 m steel basin. The mixture is fed directly into the machine from the feed hoppers. Here, solids > 0.2 mm are washed out and discharged.

The water containing the fine particles < 0.2 mm is first conveyed to a pump sump, from where the pump sump pump pumps the water from the pump sump to the supplied intermediate storage tank once the maximum fill level has been exceeded. This is equipped with an agitator, which keeps the fine particles in the residual water in motion by means of cyclical stirring. A transfer pump then pumps the water from the intermediate storage tank to the customer‘s existing recycling water tank. The water containing the fine particles is returned to the mixing process or can also be used to rinse the concrete buckets.

The systems can be equipped with the Bibko environmental efficiency package on request. The function of the developed intelligent agitator control system is to determine the density value in the storage tank, i.e., the agitator tank, 24 hours a day using an optical light absorption sensor and to make this density value immediately available to the explicitly developed and patented Bibko control system for further use. The software of this control system then calculates the optimum agitator running time for efficient homogenization based on this value.

CONTACT

Bibko

Umwelt- und Reinigungstechnik GmbH

Steinbeisstr. 1+2

71717 Beilstein/Germany

+49 7062 9264-0