Reducing cycle time during precast and tunnelling production – thanks to vacuum tilting

Many precast and tunnelling factories invest in faster production, among others in vacuum tilting. In this article, you‘ll discover how a vacuum tilter reduces handling time, frees up molds faster, and simplifies the entire post-casting process – with practical examples from both precast and tunnel segment production.

Many precast and tunnelling factories invest in faster production. But even when the casting and curing stages are in order, delays during demolding, finishing, and storing the elements can still occur, resulting in no time savings. Vacuum tilting provides a safe, efficient, and ergonomic solution.

In this article, you‘ll discover how a vacuum tilter reduces handling time, frees up molds faster, and simplifies the entire post-casting process. With practical examples from both precast and tunnel segment production, you’ll see how this approach saves time, labour, and cost, while improving output.

In manufacturing, shorter cycle times mean higher throughput and profitability. For precast and tunnel segment producers, investments in optimised casting and curing often deliver impressive gains. Yet cycle time is not determined by pouring or curing speed alone. The entire production chain – casting, curing, demolding, finishing, storing – acts like a series of interconnected links. When one link slows down, it affects the entire cycle.

The demolding process: a hidden bottleneck

Demolding, the process of removing a concrete element from its mold, sounds straightforward, but it is often where production time slows down. Traditionally, this process involves:

Waiting for the concrete to cure sufficiently to prevent damage during handling.

Using embedded anchors or clamps to lift and turn the element with cranes.

Multiple steps to tilt and position the element for curing, finishing, or storage.

If a concrete element is removed too early, it may not have gained sufficient strength, and cracking or chipping may occur. Embedded lifting points add extra preparation and patching after removal, while handling can be physically demanding and risky for workers. Operating a tilting table or forklift requires sufficient manpower, time, and a notable financial commitment for specialized equipment.

These factors combined make demolding one of the most labour-intensive and time-consuming stages in the entire manufacturing cycle.

Vacuum tilting as the solution

Vacuum tilting technology transforms demolding into a more effective process by using high vacuum that adheres suction pads securely to the surface of the concrete element without the need for embedded anchors, clamps, or additional equipment. The technology works as follows:

Vacuum creates a strong, distributed lifting force across the element. As no anchors are necessary, both material costs and procurement time are eliminated, directly improving ROI.

Due to the divided surface of the suction pads, earlier demolding is possible with less chance of cracks.

Soft rubber on vacuum pads ensures the product surface stays intact without damage.

High vacuum safely supports the weight of the element, allowing it to be lifted, tilted, and transported in one smooth movement. No additional equipment is needed.

One operator can control the process remotely, safely, and with minimal physical effort.

Quick exchange coupler ensures fast and easy suction pad exchange to fit different shapes and sizes of precast concrete elements or tunnel segments.

Compared to traditional methods, vacuum tilting is faster and safer because it reduces manual labour and risk of damage. The divided pressure across the suction pads allows for earlier demolding, so molds are freed sooner to start a new cycle, improving mold utilisation. The ability to tilt products by 90 or 180 degrees means the same equipment can be used efficiently for multiple handling steps, eliminating the need to purchase and maintain extra gear.

Technical dive-in

Aerolift vacuum tilters are designed for use with any type of crane, making them a flexible addition to both new and existing production setups. Every unit is CE certified and built with a safety factor of 2 —meaning it is designed to handle at least twice the maximum rated load, providing a wide margin of safety in real‑world conditions.

Built‑in safety systems ensure the operator always has complete control and clear feedback:

A vacuum gauge and safety lights indicate when it is safe to lift. If vacuum pressure drops below the safe limit, a red light warns the operator and an acoustic alarm prompts immediate action.

The alarm system has a battery backup, ensuring it remains active even during a power outage.

To prevent accidental release, the operator must press two release buttons simultaneously.

The valve requires a positive signal to change position—if power is lost, the valve maintains its position.

Thanks to an integrated buffer tank, the load stays securely attached for at least 20 minutes in case of power failure, exceeding industry safety requirements and giving operators time to take appropriate measures.

Optional features add an extra layer of safety, such as the safe release system that disables release buttons during lifting. This ensures unloading is only possible when the element is fully lowered.

The design is maintenance‑friendly, with pumps, filters, and valves positioned for easy access, and key components – such as rubber seals, hoses, and vacuum meters – developed in‑house to guarantee optimal quality and safety. Clear manuals, daily check stickers, and quick visual inspections help keep downtime to a minimum. With globally available components and worldwide service, Aerolift vacuum tilters deliver reliability and long‑term efficiency.

Customer story: precast production

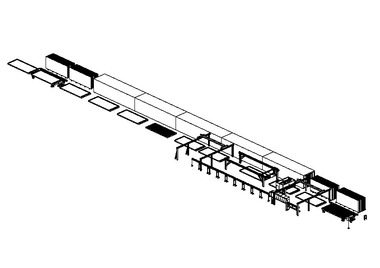

To illustrate how vacuum tilting works in practice, here is a story of Mombarg Beton, a leading Dutch precast manufacturer, which eliminated a significant bottleneck in its production process with two Aerolift vacuum tilters.

Mombarg Beton supplies a wide range of precast elements – from basements and balconies to stairs and galleries – for medium to large contractors nationwide. Until the upgrade, demolding, finishing, and storing the elements were done using embedded anchors and slings, which had to be fixed manually into the concrete, followed by separate systems for tilting and storage. This method created a bottleneck in the production process.

Frank van de Drift, Managing Director at Mombarg Beton, explains: “Even on good production days, the process would still get jammed up, resulting in no time savings. So how could we eliminate that bottleneck from the process? As there was already an Aerolift vacuum lifter in the factory, they were one of the parties we approached, and for good reason! After the Aerolift staff completed a thorough inventory of our needs, they proposed a vacuum lifter with a tilting function as the solution.”

As existing overhead cranes had limited lifting capacity and power connection, the solution involved using two identical vacuum tilters with variable frequency drives.The two machines can operate independently for smaller loads or be coupled together for larger elements. Additionally, the solution included multiple suction pads with a quick-change mechanism.

The impact exceeded expectations. “Since we started using Aerolift vacuum tilters, the cycle time has greatly reduced. Demolding is much faster and gentler because the force is distributed over the entire suction pad. As a result, there is almost no demolding damage to the mold or the element. This means the expensive mold lasts much longer, we can pour faster, and we can even manage with one FTE fewer at the finishing stage. We are positively surprised by the many advantages of the Aerolift vacuum tilters.”

Industry example: tunnel segment production

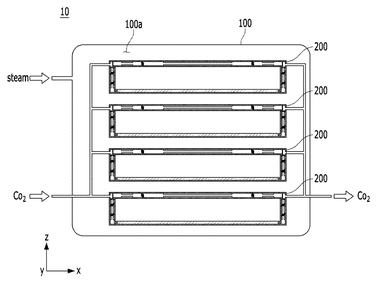

Like precast concrete elements, tunnel segments require precise production and careful handling. Afcons Infrastructure Ltd., a major Indian construction company, improved both production and storage by introducing vacuum tilters into its segment handling process.

Traditionally, tunnel segments are handled using mechanical grabs or specialized clamps, but concentrated clamping force at specific points risks surface damage or defects, leading to higher repair and rejection rates. Alternatively, vacuum lifters can be used during demolding, offering all the benefits of the vacuum technology, such as preventing damage to the segments and improving worker safety through remote operation. However, these methods require the use of turning tables to turn the segments after demolding, allowing them to be positioned correctly for further processing, storage, or transport.

The solution was to replace this two-step process with 180-degree vacuum tilters. These units lift the segment directly from the mold, tilt it, and place it on the storage rack in less than three minutes. This eliminated the need for turning tables altogether, removing the purchase, maintenance, and operating costs associated with them. As demolding can now take place after just 8-10 hours of curing, the entire production cycle has been greatly reduced. In addition, 90‑degree vacuum tilters have maximized storage efficiency by tilting segments from a horizontal to a vertical position. This allows them to be stacked upright in stable pyramid formations up to four high, reducing the required yard space by as much as 65%.

Overall, Afcons benefits from faster cycle times, lower handling costs, and reduced risk of segment damage, while making more efficient use of storage space.

Why vacuum tilting is the future

Market demands are increasing the need for faster project completion, with quality standards remaining a priority. As projects grow in scale and complexity, reducing cycle times is no longer just a competitive advantage – it’s key to meeting tight schedules and avoiding costly delays.

This requires reliable, ergonomic material handling solutions. Vacuum tilting delivers exactly that, aligning with industry trends toward faster, safer, and more sustainable production.

Conclusion

Effective cycle time depends on mastering every stage of the manufacturing process – not just casting and curing. Demolding is often where time is lost, but vacuum tilting technology offers a meaningful step forward. By reducing handling time, accelerating mold reuse, and preserving product and mold integrity, it enhances both productivity and safety. For precast and tunnel segment manufacturers looking to improve operational performance and meet tighter schedules, vacuum tilting provides a proven, practical solution.

CONTACT

Aerolift Industrials B.V.

Parmentierstraat 2A

3772 MS Barneveld/Netherlands

+31 346 35 43 33