Pyrolysis and optimized concrete curing:

Synergies for increasing efficiency and protecting our climate

Rising energy costs and the need for sustainable resource utilization are two major challenges the concrete precast industry is facing. This article concentrates on the concrete products sector to explain how combining state-of-the-art curing systems with decentralized energy generation through pyrolysis can reduce carbon emissions without jeopardizing product quality.

The entire concrete industry is facing the challenge of having to reconcile rising energy costs with the necessity of utilizing resources sustainably. This issue affects both the precast and the concrete products segment. Although relevant technology approaches are universally applicable, the considerations discussed in this article primarily relate to the manufacture of concrete products. Combining state-of-the-art curing systems with decentralized energy generation through pyrolysis is key to reducing the carbon footprint of production significantly without compromising on product quality.

Increasing efficiency through state-of-the-art curing systems

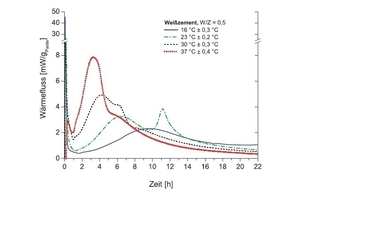

Curing is a process-critical step that has a major influence on the strength, durability, and visual appeal of concrete products. However, conventional methods often result in thermal inefficiencies and inconsistent product quality. State-of-the-art curing chambers solve this problem by enabling precise control of temperature, moisture, and air circulation.

This controlled atmosphere ensures uniform, accelerated cement hydration, resulting in higher early strength. A key advantage of this technology is its flexibility: Control parameters can be adjusted to accommodate new, less reactive low-clinker types of cement, thus ensuring consistent, reproducible outcomes even when using more sustainable binders.

Optimizing costs by reducing the number of required production boards

A frequently underestimated cost benefit of state-of-the-art curing systems is the reduced number of required production boards. Optimized process parameters allow for significantly shorter curing times – in some cases, just 12 instead of 24 hours. In one specific case, time savings reduced the number of required production boards from 6,260 to 3,620. At an estimated price of €45 per board, this would lower capex by about €118,000. However, this calculation must account for the fact that the remaining boards undergo significantly more cycles due to the reduced number held in stock. Thus, in the profitability analysis, it is important to determine whether boards sustain increased mechanical stress owing to the greater number of cycles or age-related wear over the years of their service life, regardless of the number of cycles. Additionally, costs of racking systems, factory space, and general warehouse logistics are reduced.

Pyrolysis ensures decentralized energy generation from residual materials

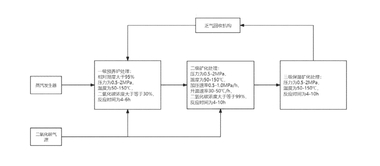

Pyrolysis offers considerable potential for meeting the sustainable energy requirements of modern concrete plants. In this thermochemical process, biomass residues such as wood chips, scrap wood, and agricultural waste decompose in an oxygen-deficient environment at temperatures ranging from 400 to 800°C.

This process results in an energy-rich pyrolysis gas that can be used in combined heat and power (CHP) plants to generate electricity and heat. This is how concrete plants can meet a sizeable portion of their energy needs autonomously without having to rely on external suppliers. Generated heat can be used for direct heating of curing chambers or other relevant thermal processes within the plant. Integrated heat recovery systems further increase the system’s overall efficiency.

It should be noted that plant and equipment must be aligned with the needs of each individual production site. While this would often make sense commercially, it is not useful to let the system’s output or energy surplus go to waste. A pyrolysis system is designed for continuous operation and usually cannot be run in stages or adjusted to changing demand. Equipment should thus be selected such that it mostly runs at full capacity, and the energy generated during operation can be utilized fully. Note that every requirement is different, and there is no standard solution that can be adapted to other plants.

Biochar: Equipment selection determines output

Biochar, the byproduct of pyrolysis, is a valuable raw material for the concrete industry. It is an extremely stable carbon sink since one ton of biochar can permanently capture up to 3.5 tons of carbon dioxide. Adding biochar to concrete mixes creates products that actively contribute to protecting our climate.

When selecting a suitable pyrolysis system, the operator’s objectives are crucial: Do they aim to produce high-quality biochar for use as a certified concrete additive, or do they want to maximize energy output for plant operation? Since commercially available systems are designed for a wide variety of use cases, relevant requirements must be defined as accurately as possible in advance. Pertinent research shows that adding biochar has no adverse effect on the mechanical characteristics of concrete when batched correctly, which is a promising outcome.

Holistic profitability analysis

Investing in modern equipment pays for itself through various revenue streams and savings. A ten-year analysis illustrates its profitability: Capital expenditure on curing chamber conversion and installation of the pyrolysis system is offset by significant savings on board purchases and revenues from biochar and carbon trading certificate sales (European Biochar Certificates; EBCs). To calculate these revenues, it is essential to attract regular buyers of biochar and certificates early in the process. Annual production of 100 tons of biochar, for instance, could generate about €60,000 in sales alone, complemented by approximately €35,000 from certificate trading. Obviously, either figure will heavily depend on the respective market environment.

Alternatively, biochar can be used directly in the company’s own plants or concrete mixes. This process also referred to as insetting enables concrete businesses to significantly reduce their carbon footprint across the value chain, including carbon trading certificates. Combining the above economic and environmental benefits while reducing the number of quality complaints thanks to more uniform curing makes this concept a sustainable investment for the industry.

Conclusion and outlook

Combining optimized curing systems, pyrolysis, and the use of biochar enables the concrete industry to decarbonize and increase efficiency. Even though each of the individual technical components has been commercially available for some time, initial integrated projects will deliver valuable long-term data in the coming months. Unlocking these synergies is another step toward achieving sustainable yet competitive concrete production.