Preco invests in digitalization to optimize the production process

Preco B.V., a leading manufacturer of precast concrete products based in the Dutch city of Apeldoorn, has partnered with Progress Software Development, a Progress Group company, to implement Erpbos, an industry-specific ERP system versatile enough to perfectly meet the company’s needs. The goal of this transformation is to revolutionize Preco’s operations and optimize the entire process chain.

Modernizing for the future

Known for its high-quality precast concrete products, Preco specializes in manufacturing walls, hollow-core slabs, and custom elements such as stairs and columns. The company’s journey began in 2004 under the name Cervix Beton, initially focusing on producing concrete elements for the agricultural sector. Over time, Preco experienced significant growth, leading to a relocation to Ede in 2012 and ultimately settling in a state-of-the-art concrete factory at the Ecofactorij in Apeldoorn in 2019.

Single, end-to-end software solution

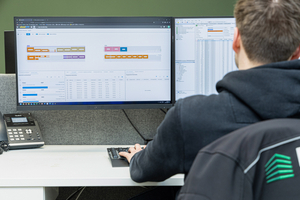

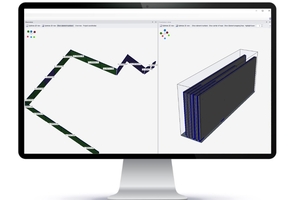

Before implementing Erpbos, Preco relied on various stand-alone software solutions that could not map every process and required a certain amount of manual effort with Excel spreadsheets to create accurate production planning. Thus, they decided to implement the new software to replace their different solutions and to switch to a single, end-to-end, integrated solution to control the entire business process. “Simply put, we were looking for an ERP system that would fully meet our requirements. And that turned out to be Erpbos,” says Bjorn Houwen, production planner at Preco. Progress customized this software for Preco by integrating intuitive 3D layout planning and a mobile application to give a transparent overview of the production planning and warehouse situation, as well as the ability to provide real-time production feedback and warehouse activity from anywhere, at any time. It now allows Preco to fully map and optimize production for all products in a single system, eliminating the need for Excel-based manual workflows while preventing flaws. This allows for better control over resources and optimizes production on tilting tables, long beds, and several manual workplaces for custom elements.

Seamless integration

The collaboration between Preco and Progress Group brings a range of improvements to Preco’s operations in an efficient, modern and intuitive way. Erpbos ensures seamless integration across departments, optimizes resource management, and enables the incorporation of BIM-based processes. The ERP system interfaces with their finance system, CAD software, and invoicing tool and controls the plotter and laser system in production. This integration ensures a cohesive flow of information and data between these interconnected systems, increasing efficiency and accuracy throughout Preco’s operations. The successful partnership between Preco and Progress Group is poised to revolutionize Preco’s operations, enhancing their competitiveness and driving further success in the precast concrete industry.

Why Progress

“There is quick and open communication, both with the project manager and with the helpdesk on the Progress side. New features have been developed together, unexpected challenges have been tackled within days or even hours. There is a real effort from both parties to make sure that the factory-specific needs are covered in a meaningful way without straying too far from the standard,” says Tim Grooteman, ERP consultant at Preco.

The biggest advantage is that Progress uses PXML files for data import. These files are multifunctional and can be used for:

Data import into Erpbos;

Ordering reinforcement;

Controlling the insulation cutter.

In conclusion, the implementation of Erpbos marks a significant milestone for Preco as they leverage the expertise of Progress Group to enhance their business processes. By replacing their previous software solutions, Preco gains a comprehensive, tailored ERP system that integrates their production planning and resource management, streamlining operations and providing a competitive edge in the precast concrete industry.

CONTACT

Preco BV

IJsseldijk 31

7325 WZ Apeldoorn/Netherlands

+31 85 112 2360

Progress Software Development GmbH

Julius-Durst-Strasse 100

39042 Brixen/Italy

+39 0472 979159