Precast concrete solution instead of timber structure for a new Hamburg landmark

The structural framework of the Edge ElbSide office building in Hamburg includes a slim-floor design composed of precast prestressed concrete floor slabs with composite beams installed flush with the floor. An earlier version of this article can also be read in the Jahrbuch Beton Bauteile 2023 (in German only) available from the Profil bookshop of Bauverlag.

The HafenCity development is an exemplary project with which the City of Hamburg is setting a new standard – at least at the European level – for a successful, integrated urban design concept that takes equal account of local needs and high standards of urbanity and sustainability. On an area of 157 hectares, a vibrant cityscape is emerging that finely interweaves the various types of use – working, living, education, culture, leisure, tourism, and retail – to create a “New Downtown” on the waterfront.

The striking Edge ElbSide office building is the second Edge project under construction in the Elbbrücken neighborhood. Located at the eastern entrance to Hamburg’s HafenCity, directly on Amerigo-Vespucci-Platz, the new landmark of the Hanseatic city is scheduled for completion by the end of 2023. Its design concept promotes a collaborative working environment in which innovative ideas can flourish.

The 16-story office building with a total rental area of about 24,000 m² provides space for approximately 1,700 workplaces. The anchor tenant will be a well-known utility company, which will occupy about 80% of the floor space.

Taking the lead

The architectural competition for the Edge ElbSide project was won by Behnisch Architekten, from Stuttgart, ahead of the Hamburg-based architecture firm Blauraum. Engineering firm Assmann Beraten + Planen GmbH was commissioned with the structural design, and Zech Group SE was appointed general contractor to construct the new Hamburg landmark from 2021 to 2023.

The new build reflects the philosophy on which Dutch real estate developers Edge base their activity: “Building a zero-carbon world. As a developer, we want to contribute to a more beautiful and sustainable world in which people and the environment are key. We take the lead in this and want to inspire others.” This is how it reads on the Edge website.

HafenCity Platinum environmental label

Edge ElbSide is set to be granted the HafenCity Platinum environmental label and the Well Core & Shell Gold certification from the International Well Building Institute (IWBI). The latter certificate assesses the general degree of innovation of buildings and measures that explicitly addresses the health and wellbeing of users.

In the Edge ElbSide project, the technological strategy aims to maximize sustainability based on the Edge Next platform. The innovative plug-and-play multi-sensors installed in the building simultaneously measure air quality, lighting conditions, indoor temperature, and room utilization. This data is then broken down to a high degree of detail in the cloud and automatically adjusted to achieve maximum energy efficiency. Employees can use a connected building app to individually control light intensity and temperature, among other parameters. In addition, photovoltaic panels will be installed on the rooftop.

Precast concrete solution more appropriate than timber structure

During the design process, the project stakeholders were confronted with unexpected problems. The competition brief specified an all-timber structure to meet sustainability requirements. However, the winning entry featured multi-story conservatories, open-space units with wide-span ceilings, and clear-span, convertible rooms and galleries. The question arose whether the envisaged timber structure was still the right solution.

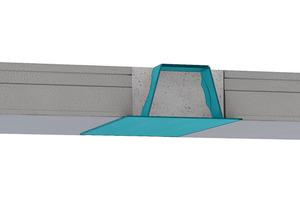

The intended design concept consisting of glulam double columns and hybrid floors made of timber-concrete composite elements had to be abandoned because this option made it impossible to meet the demanding requirements for the load-bearing structure and for fire safety in a commercially viable manner. Three structural alternatives were investigated: a flat floor with joists installed flush with the slab, a flat floor with flat joists, and precast prestressed concrete slabs with composite beams installed flush with the floor (i.e. a slim-floor design). Engineering firm Assmann prepared a comparative analysis resulting in the selection of the prefab solution involving precast prestressed concrete floor slabs and composite beams.

Its benefits included faster construction progress, a low shell height despite wide spans (with a slab thickness of 26.5 cm and a maximum column-to-column spacing of 9.45 m), material savings (about 50% less concrete and 80% less steel than with non-prestressed reinforced concrete floor systems) and thus a lower total weight of the building, as well as reduced greenhouse gas emissions (approx. 20% less CO2) and energy consumption (approx. 20% less primary energy) compared to the other concrete floor systems.

This makes Edge ElbSide Germany’s tallest slim-floor office building. Loads are transferred to the foundation piles via a reinforced-concrete column framework, which also accommodates the prefabricated aluminum façade sections with projecting vertical pilaster strips or fins in the exterior areas.

An office building as a “marketplace”

Edge ElbSide Hamburg goes beyond the run-of-the-mill, dull sequence of separate offices arranged along corridors. Instead, it promotes open, extroverted communication between individuals and their surroundings – after all, everything revolves around the people who enter their world of working.

Via the internal entrance plaza, an inviting open staircase connects to the mezzanine floor. From there, an open staircase installed in the area of the so-called Magistrale, the communicating “marketplace”, allows for vertical circulation across six floors. The Edge ElbSide building features green conservatories that form intermediate indoor climate zones. They open up across stories, can be used all year round and are dispersed throughout the building. As part of the overall air-conditioning concept, they create buffer zones in which fresh air is preheated, thus allowing for controlled natural cross-ventilation within the office building. They also significantly reduce energy consumption. In the tower area, two-story atria lend additional spaciousness to the work areas and facilitate communication between the levels since they create individual places to meet and work. The conservatories also serve as landmarks along the “main street”. The energy concept aims to maximize modularity, flexibility and living quality in harmony with the environment. For this reason, the conservatories are deliberately employed as a feature to establish a connection between the exterior and interior of the building.