Precast concrete climate control walls from ABI for Cologne city archive

At the end of October 2023, Syspro-Gruppe Betonbauteile and one of its members, Andernacher Bimswerk GmbH (ABI), welcomed trade journalists to the Bedburg precast plant. In 2018, this plant had produced climate control walls that ensure a reliable indoor climate in the storage facility of the new Cologne city archive.

The construction of the new Cologne city archive posed a particular challenge in the wake of the catastrophic collapse of the old building in 2009. “The new building had to function perfectly and safely,” explains former project manager, Werner Engels, in his presentation on the requirements specified by the City of Cologne. The ambition was worded very clearly: “We were requested to build the most modern and safest archive north of the Alps,” comments the now retired project manager on the most daunting task in his professional career.

His audience – quite a few trade journalists – had already visited the Bedburg production site in the morning of this Syspro press day. This is where the precast elements that now play a crucial role in the design of the new city archive building were manufactured in 2018.

City memory takes center stage

The new archive building cost 90 million euros. It was constructed between 2017 and 2021 and provides space for Europe’s largest paper restoration workshop where 30 conservation specialists and 50 assistants work. The entire complex stretches over an impressive length of 126 meters; it is 45 meters wide and approximately 11 meters high. The building’s real “treasure trove”, its central storage facility, is located in the middle of the site, surrounded by the building wings.

“This is where archived items from over 1,000 years of Cologne’s city history are stored on six floors,” says Alexander Berger, Head Archivist, in relation to the holdings that are of immeasurable value since they represent the “city memory” of the Rhine metropolis.

Temperatures between 16 and 22° C and a humidity between 40 and 55% ensure an indoor climate that is safe for conservation purposes. Yet the stock of film materials requires even more demanding storage conditions at a temperature of -18° C. The entire building complex comprises nine different air-conditioning zones.

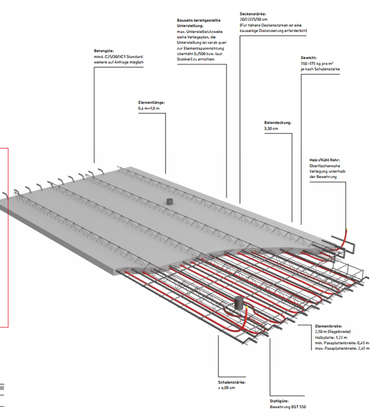

Building envelope with integrated pipe coils

To ensure the required climatic stability in the storeroom, the windowless building block was fitted with Syspro climate control walls on all façades and on the roof. A temperature-controlled fluid circulates in the integrated pipe coils, ensuring that heat input can be controlled very precisely. In the summer and winter seasons, temperature peaks are thus kept away from the actual (load-bearing) concrete structure of the archive building.

The design also includes a specific safety feature: The pipes were installed outside the load-bearing structure, behind the metal façade, which prevents fluids from spilling into the archive’s interior in the event of a breakdown or accident.

The inner and outer shells of the 30 cm climate control wall panels have a thickness of 6 cm and 8 cm, respectively. On their outside, the cladding walls include recesses in which ducts for the vertical pipes connecting to the air-conditioning system are routed.

“One of the most important design details is that the installed pipe system can always be checked for leaks,” explains Ralf Nienhaus, Technical Manager at Andernacher Bimswerk GmbH.

For the storage facility, ABI supplied 170 wall panels covering a total area of 2,830 m², which is equivalent to 410 m³ of concrete and 51 tons of steel. Eleven kilometers of pipes were installed in the multi-layered walls of the building envelope. From the inside to the outside, these layers include the load-bearing structure of the concrete building, the heatable and coolable precast elements from Bedburg attached to it, a thermal insulation layer, and an external metal façade. “This design principle is unique on a global scale, preventing abrupt temperature variations and moisture ingress in the interiors,” explains the archivist, describing how the walls work during a tour of the storeroom. During a stop in a vacant archive room, project manager Engels explains how the preliminary design for this special building was developed: “We had to consider many different parameters in collaboration with the building physicists: Building moisture, moisture ingress from employees present in the storeroom, and regional climate changes were all factored into the equation. We are positively surprised at how accurately these scenarios match the in-service conditions.”

Reducing building moisture to a minimum

“It was precisely because they wanted to operate with as many reliable parameters as possible on-site that resorting to our Syspro climate control walls was so obvious. The fact that we can reproduce the quality of the components with pinpoint precision played a major role,” said Ralf Nienhaus during a discussion with the journalists at the Bedburg plant. “Compared to conventional cast-in-place concrete walls, the double wall panels with their core cast on-site allow for only a minimum of building moisture to be generated,” says the Technical Manager, explaining the seamless network of heating and cooling pipes that can even be partially controlled throughout the building envelope depending on the position of the sun.

Archivist Andreas Berger confirms that the interplay of the specific combinations of building services has attracted a great deal of interest among civil engineers, architects and archivists since the grand opening of the building. “Experts from across the world visit us to learn more about the details.”

The project had significant implications for the production of Syspro elements at the ABI plant: “We gained a huge amount of experience that significantly refined the integration of the heating modules into our climate control elements,” explains Ralf Nienhaus during the tour of the Bedburg plant. The project has also raised further awareness of the technology. “We currently produce climate control elements on a regular basis and already ship between 2,500 and 5,000 m² per year,” adds the Technical Manager.

This trend is also gaining ground in other Syspro group companies. “Climate control walls and floor slabs are becoming increasingly important in view of the ever-increasing requirements for highly energy-efficient building envelopes,” confirms Syspro Managing Director, Dr. Thomas Kranzler. In discussions with member companies, he learned that it is exactly the perfect climate control and highly precise industrial prefabrication that makes this construction method particularly attractive for the commercial and residential sectors going forward.

CONTACT

Syspro-Gruppe Betonbauteile e. V.

Matthias-Grünewald-Str. 1-3

53175 Bonn/Germany

+49 228 37756322

Offices, laboratory and archive

Waechter + Waechter, Darmstadt

90 million euros