Polymer fibers for concrete reinforcement and intelligent planning software

Sika has micro and macro polymer fibers in its portfolio, from which manufacturers of concrete goods and precast elements, among others, can profit. With SikaFiber software, it is simple to determine the optimal combination of slab thickness, concrete quality and fiber content for the intended loading.

Polymer fibers are multi-talents for concrete reinforcement. These high-performance fibers can reduce or totally replace typical steel reinforcement, improve the resistance to shrinkage cracks, increase post-cracking flexural bending strength, optimize mechanical properties and prevent concrete spalling in the event of fire. Sika has micro and macro polymer fibers in its portfolio from which, depending on the area of application, manufacturers of ready-mixed concrete, precast elements and concrete goods as well as dry mortar can profit. With SikaFiber software, the optimal combination of slab thickness, concrete quality and fiber content can be simply determined for the intended loading.

Strict safety regulations, extraordinary architecture and multiple functionality present enormous challenges in the field of concrete as modern construction material. Polymer fibers from Sika stabilize concrete and provide it with firmer structures.

Macro fibers for precast elements, architectural concrete and shotcrete

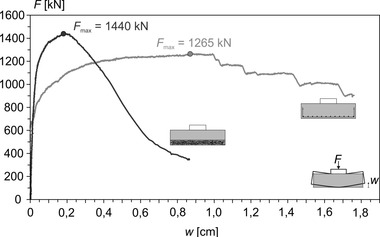

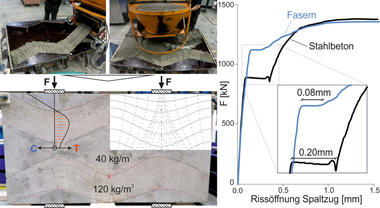

With SikaFiber macro fibers, the mesh reinforcement in concrete ground slabs can be partially or completely replaced, which saves time and money in the construction process. Macro fibers, in comparison to steel reinforcement, are homogeneously distributed in the concrete, increase bearing strength and post-cracking flexural bending strength as well as strengthening it up to the surface. Micro fibers, in addition, have a lower CO2 footprint than steel reinforcement. SikaFiber is simply added during concrete production and is especially effective during hardening of the concrete and in strengthening surface, edges and corners.

SikaFiber Force-50: the structurally effective micro fiber for precast elements and architectural concrete

SikaFiber Force-50 is used, for example, for concrete ground slabs, precast elements, ground stabilization and foundations – as well as in the construction of transportation systems. Since the danger of corrosion no longer exists, Exposure Classes XC (corrosion of reinforcement due to carbonation) and XD (corrosion of reinforcement due to chloride) as well as the concrete cover thereby reduced, enable more slender construction components. In concrete floors, the elimination of steel reinforcement allows direct trafficking with truck mixers — making the use of concrete pumps unnecessary. Micro fibers improve the fatigue behavior of dynamically loaded traffic surfaces and therefore prolong their service life. The product has been certified in accordance with DIN EN 14889-2, Class II, and its structural effectiveness has been confirmed by national technical approval DIBt Z-3.73.2149.

SikaFiber Force delivers genuine added value

The fibers made of polypropylene are packed as water-soluble pucks and are optionally available in paper bags of 3 and 5 kg, or in Bigbags of 400 kg. They are therefore suitable for use in automated batching systems and are more easily distributed in concrete mixers. Their manufacture in Germany increases delivery reliability, shortens transport routes and reduces the CO2 footprint.

Sika also offers for SikaFiber Force-50 its comprehensive range of services. Customers can rely on correct structural analyses, reliable delivery as well as competent application engineering for admixtures.

Micro fibers for reducing shrinkage cracks

Concrete floors and other construction components with large surfaces are extremely vulnerable to the formation of shrinkage cracks that result from the evaporation of water from the concrete. SikaFiber PPM micro fibers reduce shrinkage crack formation by more than 90 % by inhibiting possible formation of micro cracks, which thereby presents harmful crack enlargement. The fibers were, for example, used in the rehabilitation of the Bergedorf bus terminal in Hamburg. On an area of approx. 3,800 m2, Sika installed over a period of three days 420 m3 of shrinkage-reducing fiber concrete, with SikaFiber PPM-12 C30/37 micropolymer fibers and the shrinkage reducer SikaControl-40. The polypropylene fibers serve primarily for risk control due to shrinkage as well as for increasing tensile strength in uncracked condition.

Micro fiber for use in fire protection

Sika Crackstop fibers play an important role in preventive structural fire protection in that they melt in the event of fire by enabling non-pressurized escape of the water vapor that is formed in the concrete. This prevents spalling of the concrete and collapse of the concrete component.

These fibers are primarily used for fire protection in segmental linings and interior tunnel shells; they may, however, also be used for fire protection in building construction. In the manufacture of prestressed concrete beams for covers in front of the Altona Tunnel entrance, Sika Crackstop fibers were, for example, used to satisfy the requirements of fire protection. The special feature: the micro polymer fiber, in a water-soluble paper bag, can be directly added into a compulsory mixer — the paper bag dissolves without residue.

Complex analyses within a minimum of time with SikaFiber software

SikaFiber software for Windows operating systems helps structural engineers and all those concerned with the construction and design of concrete ground slabs who determine the optimal combination of slab thickness, concrete grade and fiber content for the intended loading. This software is based on international EC2 and TR 34 Technical Reports and enables complex calculations within a minimum of time. Following entry of various parameters, the software checks whether the choice of concrete grade, fiber concrete and slab thickness is sufficient for the intended loading. By the green checkmarks or the red crosses, users can easily recognize where adjustments should be made. The calculations can be subsequently clearly arranged and exported for digital and printed documentation.

SikaFiber software helps with correct batching: for example, of SikaFiber Force-50 polymer fibers, which are filed in the software.

The latest, cloud-based version of the software will be available shortly.

CONTACT

Sika Deutschland CH AG & Co KG

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0