Jasto Baustoffwerke opts for automation for highest quality in color in collaboration with H. Scholz

At Jasto Baustoffwerke, a comprehensive modernization project, implemented in 2016, gave rise to the commissioning of a new color metering system of H. Scholz, that convinces by its performance and mechanical features. Karla Knitter and Kristin Hanneforth of BFT International visited the factory site and summarized the most impressive aspects of this cooperation.

The history of Jakob Stockschläder Bau- und Brenn-stoffe goes back to the year of 1949, when Jakob Stockschläder, being 19 years old at that time, established a factory in the Rhineland-Palatinate municipality of Ochtendung for the production of masonry blocks made of the Rhenish pumice – a lightweight building material that was deposited in large quantities in the Neuwied Basin because of the eruption of the Laach volcano about 13,000 years ago. Until today, this special geological feature is the basis for the regional building materials industry and laid the foundation for the Jasto company too.

In the following decades, the company has been evolving to an important player both in the production of masonry blocks and in the lightweight concrete industry. Due to continuous modernizations – including the installation of a fully automated production line with integrated drying chamber – and the expansion of the operating space to approx. 300,000 m², the company was able to enhance its operational performance continually. At the end of the 1990s, the brand „Jasto Baustoffwerke“ has been established and more and more replaced the still valid company name „Jakob Stockschläder GmbH & Co. KG“ in public communication. In 1997, Ralf Stockschläder assumed the business management with a staff team of over 100 people. Despite the growth in the meanwhile 75-year company history, Jasto still is a family business – employing long-term staff members, some of whose families have already been working with the company for several generations.

With the worlds of fireplaces, gardens and construction, Jasto makes a contribution to the design of housing and living spaces till this day: More than 190,000 families have created living spaces using Jasto products; more than 100,000 gardens have been realized with them.

Color dosing technology as key to diversity

The possibility to offer concrete blocks in diverse color shades is a deciding competitive factor. Customers attach ever more attention to individual design solutions, making colored products particularly attractive. While the technological requirements on the production are increasing simultaneously. A consistently high color quality and exact dosing require the use of modern color metering systems, working precisely and efficiently.

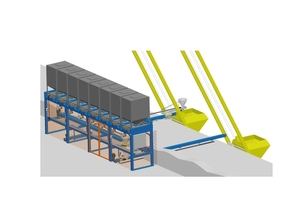

In 2016, Jasto commissioned the „Grapados 8“ granule metering system made by Harold Scholz & Co. GmbH. The system is provided with eight receiving positions for pigment containers with a capacity of 1,700 l each. Each position is equipped with a storage and discharge hopper with a capacitive level sensor and a metering butterfly valve for pigment dosing. A special weighing system allows for residual emptying and a quick container change, supporting automated dosing of additional colors. A linear transportation system with a mobile weighing unit in a three-point suspension is situated below the plant, traveling to the color positions (driving speed approx. 1 m/s). The weighing unit passes the pigments on to one of two conveying vessels via a butterfly valve. The vessels are mounted to a linear transportation system running in transverse direction and are discharging the pigments into the respective elevator bucket. A storage tube inside the elevator bucket provides for a pinpoint color dispense into the aggregates. It is possible to operate both buckets simultaneously.

Robert Getta of the Technical Marketing Department at Harold Scholz highlights the specific characteristics of the color metering system: „A special feature of this system, on the one hand, is the container solution, providing for an extremely compact design, with allowing very fast color changes at the same time. On the other hand, two linear units ensure that the pigments get directly into the elevator bucket in a dust-free manner, being then conveyed into the mixer.“

Individually developed design for special requirements

In 2012, Helmut Faber (Harold Scholz) developed the first prototype because of a quite specific requirement – a customized solution for particularly demanding conditions. The system was conceived, manufactured, and commissioned at the customer with success.

Since then, more than 20 additional systems were realized – each tailor-made and adapted to the specific requirements and framework conditions of the customers. Each of these systems is unique and part of a continuous further development. The Jasto company was also faced with a challenge, that required a special solution. Jan-Peter Kutz, Sales Manager at Harold Scholz: „In this case, the situation was a bit more difficult, as far as feeding the pigments from the metering system into the elevator bucket was concerned. We have realized this in a customized solution.“

A key advantage is the considerably reduced space requirement of the Grapados 8 – at an overall height of approx. 4,400 mm and an overall width of 8,300 mm, the footprint can be reduced by about 40 %, what is a significant advantage, in particular, in case of large-sized production plants.

Feeding from one side by a fork-lift and the low height ensure a space-saving integration in the existing production lines without requiring any additional operator platforms. Even in case of using containers, a special mechanism allows for opening and closing from ground level, with improving the workplace safety.

Positive conclusion of all project parties

Ralf Stockschläder, General Manager of Jasto, is very satisfied: „When the system was presented to us as a prototype, we were convinced by the performance and the mechanical features. We are very satisfied with the performance, the system is running in 24-hour operation, at six days a week in a smooth manner.“ Jan-Peter Kutz, Sales Manager of Harold Scholz adds: „We are very proud that we have been able to accompany the new construction of Plant 1 with our metering system and our pigment granules.“

CONTACT

Jakob Stockschläder GmbH & Co.KG

Koblenzer Straße 58

56299 Ochtendung/Germany

+49 (0) 2625 / 96 36-60

Harold Scholz & Co. GmbH

Ickerottweg 30

45665 Recklinghausen (Suderwich)/Germany

+49 (0) 23 61 - 98 88-0