Intelligent production control in concrete block plants with PIMS

Production planning in block and paver plants requires careful coordination of all steps to ensure efficient and high-quality manufacturing. Modern technologies, as well as software-supported planning and digital monitoring tools, play a crucial role. To produce in a highly customer-specific yet cost-effective manner, block and paver plants must be utilized to their full capacity.

Production downtimes caused by cycle time differences

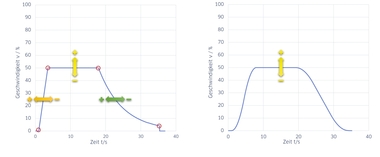

In just-in-time production or when running high volumes of a single product, production-related downtimes can occur repeatedly. These downtimes are typically caused by the simultaneous processing of different products on the wet and dry sides (stacking). For example, if heavy and large products such as curbstones are produced on the wet side, while standard block and paver products are being manufactured on the dry side, the board buffer inevitably fills up over time, slowing down the dry side.

Conversely, short cycle times on the wet side combined with longer cycle times on the dry side can result in a board shortage or a full curing chamber, which in turn slows down the wet side. Since all production data is already captured in a Hess plant, the new Plant Information Management System (PIMS) software module offers an effective the solution.

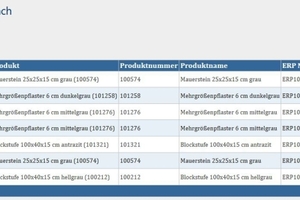

Digital recording and planning of production orders

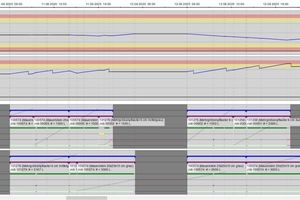

In the first step, all customer orders are recorded in a planning table. This can also be done automatically via an interface with the customer’s ERP system. Based on this planning, the system calculates the utilization of the wet side, the development of curing chamber occupancy, the status of the board buffer, and the possible packaging of finished block and paver products after curing. The foundation of planning is the block and paver product portfolio with its typical cycle and utilization times of the plant. For new products, these have to be defined via a parameter page. For products that have already been produced, the cycle times are known and can easily be retrieved from existing data of previous production runs.

Through a clear visualization of production over time, bottlenecks and downtimes can quickly be identified, and the production plan can be adjusted as needed. This requires manual adjustments in the planning table, i.e., manually rescheduling the orders and rerunning the simulation. The previously mentioned bottlenecks in the curing chamber and board buffer are identified and displayed visually along with the planned production. The optimized plant utilization can then be easily transferred into the Hess order list. Here, yellow indicates a warning threshold, while red signals a critical condition requiring action.

Improved efficiency through optimized production processes

By optimizing plant utilization in this way, downtimes caused by bottlenecks are avoided, workforce resources are used more efficiently, and the prediction of order completion (just-in-time production) improves the customer’s logistics system. An “offline planning” of upcoming orders is possible, and setup and maintenance times can be included in the plan.

This software isfully integrated into the Hess plant visualization and Hess Statistics.

CONTACT

Hess Group / Topwerk Group

Freier-Grund Str. 123

D-57299 Burbach-Wahlbach

+49 2736 4976 0