Glass GmbH modernizes Production Line with new Battery Formwork

With a customized battery formwork from Ratec, Glass GmbH Bauunternehmung in Mindelheim has renewed its production capabilities.

The Glass Group, headquartered in Mindelheim, is one of the most significant construction companies in southern Germany. On its over 170,000 square metre site, the family-run business, now in its third generation, operates, among other things, its own precast concrete plant. With approximately 555 employees at this location, Glass covers almost all areas of construction – from civil and bridge engineering to building construction and turnkey industrial and commercial projects.

Modernization of the Production Line

The collaboration between Glass and Ratec emerged in the context of modernizing the existing production line for large-format precast concrete elements.

Glass already had an older battery formwork with a pit, which was, however, technically outdated. The aim of the project was to modernize production with a new, precise, and user-friendly battery formwork – while retaining the existing infrastructure. The requirements for the desired formwork were demanding: smooth surfaces on both sides, minimal dimensional tolerances, suitability for self-compacting concrete, and precise integration into the existing structural conditions.

Key factors in the decision in favour of Ratec were, in addition to the technical expertise of the development team, the detailed project support, geographical proximity, flexibility in adapting to local conditions, and the cooperative partnership.

Key Features of the Technical Solution

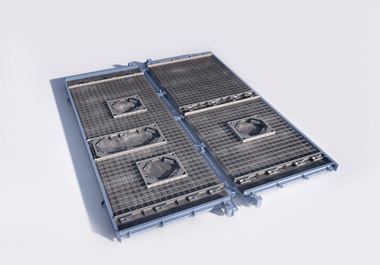

The installed solution is a battery formwork with 2 × 3 pockets, designed for elements with a net size of up to 8.00 m × 3.55 m and wall thicknesses from 10 to 25 cm. The elements are primarily used in industrial and commercial construction, where high dimensional accuracy and surface quality are required.

During the project, several customer-specific requirements had to be fulfilled:

Integration into the existing pit:

The new battery formwork was integrated into the pit of the previous system, allowing the existing infrastructure to be reused and minimising conversion effort.

Stability and dimensionalaccuracy:

Due to the high requirements for the flatness and dimensional accuracy of the produced concrete elements, the formwork was designed to be particularly torsion-resistant. Panels are clad with 10 mm thick steel sheet, with a flatness tolerance of ±1.5 mm over 3 m, ensuring consistently precise production results.

Self-compacting concrete:

The system is designed for filling with self-compacting concrete (SCC). Concrete is poured from the top, with each pocket able to be filled independently. Concrete pressure is absorbed via the outer tension walls against the central tension wall.

Hydraulic clamping:

A hydraulic clamping unit with 2 × 4 cylinders per side ensures uniform pressure distribution and reliable clamping during concreting and curing.

Magnetic formwork system:

The magnetic formwork components enable rapid adaptation to different element heights and geometries.

Continuously adjustable wall thickness:

Variable top angles and top boxes allow wall thicknesses from 100 mm to 250 mm to be adjusted continuously without additional conversion time.

Ergonomic operation:

Operation and access to the formwork are facilitated by integrated walkways and the new scissor lift platform with a 1,000 kg load capacity, enhancing both safety and productivity. The formwork was precisely matched to the existing pit and, in combination with the new lift platform, constitutes a modern, ergonomic, and safe production unit. In close cooperation between the customer and the technical team, a solution was developed that considered all safety requirements – such as railings, stair access, and statutory regulations.

Positive Overall Assessment

Franz-Rainer Göhrle, Head of the Precast Plant at Glass, gives a positive summary: “The collaboration with Ratec was extremely pleasant on all levels. As a customer, we always felt very comfortable and had the impression that all employees involved in the project carried out their work with genuine passion. We had a shared goal in mind, and it was pursued with dedication by both parties. From our side, great praise and thanks to all Ratec staff!”

Both the technical implementation and project organisation met the high expectations. Timely delivery, high professional expertise, and open, respectful communication characterised the collaboration.

“We are very grateful to Glass for giving us the opportunity to demonstrate our capabilities,” says Jörg Reymann, Managing Director of Ratec GmbH. “Every solution we provide is developed in close consultation with the customer – we do not sell off-the-shelf standards. We take their requirements and wishes seriously and develop a solution that fits perfectly to each plant and its individual workflows. This is what makes such projects so special for us.”

The installation of the new battery formwork in Mindelheim demonstrates that the success of such projects lies primarily in open communication and careful coordination between customer and manufacturer – with a solution that optimally supports operations on-site. Ratec once again proved its expertise in developing customized solutions. Customer satisfaction is always the top priority.