Faster and more material-efficient bridge construction with thin-walled structural precast elements

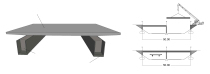

The Technical University of Vienna (TU Wien) has developed a new construction method for the fast and material-efficient construction of post-tensioned concrete bridges. The development of the LT bridge construction method drew on experience gained with the construction of bridges with thin-walled precast girders erected over the Lahnbach and Lafnitz Rivers and with the first application of the balanced lowering method. An LT bridge consists of thin-walled longitudinal girders with box cross-sections, deck slab elements arranged on the longitudinal girders, and a layer of concrete cast on top of the deck slab elements and the longitudinal girders. The concrete topping and the starter bars connect the longitudinal girders to the deck slab elements.

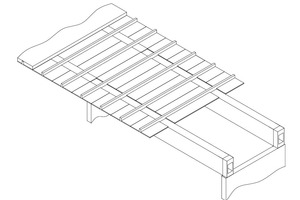

Fig. 1 is a simplified representation of the LT bridge construction method, which is especially suited for the construction of post-tensioned multi-span bridges. Fig. 1 shows a configuration during the construction of a bridge section. The post-tensioned precast girders are arranged in the longitudinal (L) direction. The deck slab elements are installed on the longitudinal girders in the transverse (T) direction. Fig. 1 shows a configuration where four of six deck slab elements are placed. The entire transverse reinforcement, the stirrup reinforcement, and the lower longitudinal reinforcement have previously been installed in the precast plant. Utilization of the precast elements and minimization

of the reinforcing steel installed at the construction site enables the construction of sections with a span of 25–60 m in weekly cycles.

Construction of the first LT bridge took place in 2022 as contracted by ÖBB Infrastruktur AG. Constructing the superstructure of a single-span frame bridge in three and a half days was possible. 40 % of the concrete mass required in the initial planning was saved. In January of 2023, ÖBB Infrastruktur AG commissioned the planning of an

additional bridge using the LT bridge construction method.