DfMA in Construction: Potentials, Benefits and Perspectives

The construction industry is facing major challenges: rising costs, labor shortages, and the demand for greater sustainability are fundamentally calling current building methods into question. This is exactly where Design for Manufacturing and Assembly (DfMA) comes into play: a forward-looking approach that incorporates manufacturing and assembly considerations at an early design stage and thus offers numerous advantages.

What is DfMA?

Design for Manufacturing and Assembly is more than just a buzzword: DfMA is transforming the fundamental methodology of how we approach new building projects. Instead of designing buildings as one-off, bespoke projects, DfMA integrates the requirements of manufacturing and assembly from the very beginning of the design phase. The goal? Every component should be as simple as possible to produce, transport, and assemble. This reduces waste, avoids errors, and accelerates schedules.

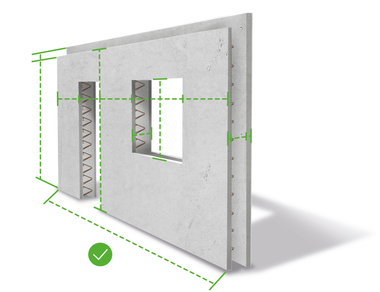

Originally used primarily in industries such as automotive and consumer goods, the concept is now increasingly applied in construction. In industrialized prefabrication and modular construction, building components are manufactured under controlled conditions in a precast plant and then assembled on site. This increases component precision and facilitates installation on the construction site.

Precast construction is already increasingly used in residential complexes, industrial buildings, and office developments. Precast concrete demonstrates how aesthetic, versatile, and sustainable it can be. In modular construction, entire building sections or even whole rooms are manufactured as modules, transported to the construction site, and assembled there. This method has proven particularly effective for projects requiring speed and scalability, such as hospitals, hotels, or social housing.

Why is DfMA important?

DfMA offers the AEC industry numerous advantages:

Time savings: Prefabrication and optimized assembly accelerate project completion.

Higher precision: The factory environment enables stricter quality control, reducing rework and on-site errors.

Greater safety: More work in controlled factory settings and less time on site reduce risks for workers.

Sustainability: DfMA promotes resource-efficient planning and building, reduces waste, and lowers energy consumption.

Cost control: Standardized components and digital workflows make cost forecasting more reliable.

Better collaboration: Early involvement of all project stakeholders fosters shared understanding and smoother project delivery.

Technology: The Backbone of DfMA

Digital tools are indispensable for implementing DfMA. Modern AEC software enables teams to incorporate manufacturing and assembly requirements during planning, coordinate across disciplines, and generate precise data for off-site production.

Key functions for DfMA include:

3D modeling for accurate quantity take-off and cost planning

Comprehensive quality checks already in the design phase

Cloud-based platforms for real-time collaboration and logistics management

Integration with Manufacturing Execution Systems (MES) for seamless data flow from design to production to assembly

Automated generation of precise production data

AEC software for DfMA should therefore enable end-to-end data flows and provide access to the latest plans and production data.

How Allplan supports the DfMA approach

In short, DfMA is about making the right decisions at the right time in construction projects. Allplan’s “Design to Build” philosophy provides architects, engineers, and construction professionals with the necessary tools and information to make data-driven decisions at an early stage. From the first design concept to detailed production and assembly planning, every step of the process can be productively managed and coordinated with AEC software solutions. This enables seamless collaboration and ensures an efficient flow of information across all disciplines.

What does “Design to Build” mean for Allplan?

Tools and information for early data-driven decisions and better results

Automation of standardized design tasks, including digital manufacturing processes and DfMA

Project-wide use of BIM models to optimize procurement, fabrication, quality assurance, and construction

Allplan thus pursues an integrated, digital approach that helps AEC professionals deliver building and infrastructure projects more productively, safely, and sustainably.

DfMA as a Competitive Advantage

Modular construction and prefabrication are the future of building. Experts forecast a growth rate of ten percent for DfMA between 2024 and 2027. Companies that engage with Design for Manufacturing and Assembly today will secure a clear competitive advantage.

Would you like to learn more about DfMA? Deepen your knowledge with the free eBook “Understanding DfMA: Design for Manufacturing and Assembly in Fact Check.”

CONTACT

Allplan Österreich

Urstein Süd 19/1/401

5412 Puch bei Hallein/Austria

Christiane Ganster-Rathgeb

Allplan.com/precast