Calcined clays in CO2-reduced cements –

challenges ranging from raw materials to concrete

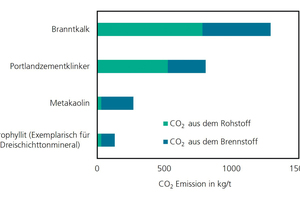

The climate protection aims of the German government call for fast and effective action for conversion to CO2-neutral production methods. For the industrial area of action, amendment of the German Federal Climate Protection Act specifies for 2030 maximum emission quantities of 118 million tons of CO2 equivalent. This corresponds to a reduction of 31 % relative to the CO2 equivalent emitted in 2020 – a development which presents considerable challenges, in particular to the cement and concrete industry. Whereas so-called breakthrough technologies, as those involving carbon capture, storage or utilization, as described in the published roadmaps, will not effectively contribute to reduction of emissions until beginning in 2030, effective leverage is available already today: reduction of the clinker content in cement and of the cement content in concrete.

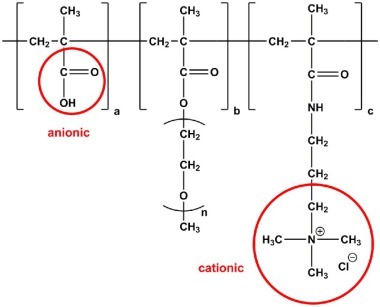

In view of the forecast decrease in the quantities of fly ash and blast-furnace slag produced, calcined clays will play a critical role in this connection. Although clays are available in sufficient quantities the world over, identification and selection of suitable local clay deposits often represent a challenge. Clays and marls have been used as raw materials in clinker production for many years now, but with a clearly different requirement profile than in production of supplementary cementitious materials. The questions that arise range from characterization and suitability testing of raw clays to the calcination process, and extend to the influence on fresh and hardened concrete properties. These issues have been topics of numerous research projects and were summarized, for example, in RILEM TC 282-CCL in the form of several white papers. The presentation provides a survey of the challenges faced in using calcined clays in cements with low clinker content throughout the entire production chain, and of the resulting opportunities for optimizing the CO2 balance of concretes.