Structural precast elements from Riga for Europe

Skonto Prefab, the precast concrete division of the Skonto Enterprises group of companies, is one of the biggest, state-of-the-art manufacturers of structural precast concrete elements in the Baltic States.

What started with the aim to supply customers of the surrounding region with a standard product portfolio of concrete components, Skonto Prefab based in the Latvian capital city of Riga is now, a good 10 years after its foundation, a company with a workforce of 200 people manufacturing all kinds of structural reinforced concrete elements with a corresponding annual turnover of €16 million (2013). A major part of these products is exported to European countries, primarily to Scandinavia.

The Skonto group of companies, comprising a total of 40 companies and a workforce of 1,500 people which generate an annual turnover of €300 million, is one of the biggest production and construction companies in Latvia and export division’s Skonto Enterprises subsidiaries in Germany, Norway, Sweden, Denmark, and Great Britain. Another important business unit is the production of glass, plastics, aluminum and steel constructions by Skonto Plan.

Monthly output of 20,000 m²

floor slabs and 6,000 m² wall panels

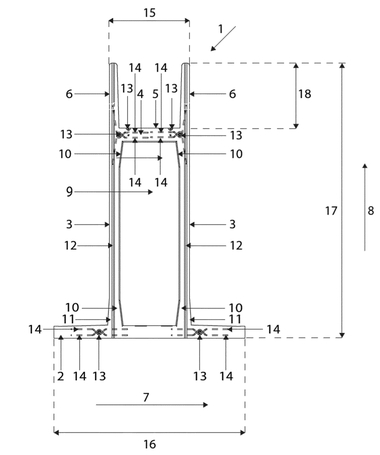

General Manager, Karlis Roznieks, proudly presented the most essential key figures to the participants of the study group from Germany, stating: “We have a production capacity of about 20,000 m² of prestressed hollow core slabs, 6,000 m² of solid wall and sandwich wall panels as well as 5,000 m² of filigree floor slabs per month, added by a not inconsiderable number of columns, prestressed beams, staircase and balcony elements as well as slabs in custom-made design and base plates in various dimensions, which are certified according to EU standards. Up to 25 loaded trucks leave our factory premises every day towards the Baltic port of Riga that is just 20 km away allowing fast and reliable delivery of the concrete products to our international customers.”

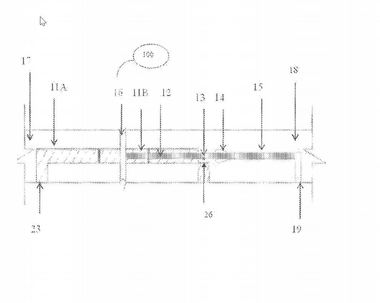

There are five production lines each 140 m long for manufacturing the prestressed hollow core slabs; they are available in slab thicknesses of 200, 220, 265, 320 and 400 mm. The filigree floor slabs are manufactured on two production lines of 60 m lengths each comprising a reinforcing steel bending station. The production line for the sandwich slabs, base plates, solid wall elements and slabs in custom-made design is equipped with hydraulically driven, heatable tilting tables. The production technology almost without exception comes from the Finish machinery and equipment suppliers Elematic and Extec respectively; the indoor cranes were delivered by the German supplier Konecranes in various load classes up to 20 tons.

Textured formliners and colored

concrete for sandwich elements

Karlis Roznieks, General Manager, accompanies the visitors through the production halls and points out the company’s very successful exports of wall elements: “Our sandwich wall elements are virtually predestined for the Scandinavian markets not only because of the climatic conditions there. From the standard element to an architecturally demanding façade provided with very precious surfaces and colors, we are able to supply a wide range according to customer requirements. The thermal insulation layer arranged between the two concrete layers totally eliminates any elaborate and expensive additional insulation.”

This is, among others, due to the textured formliners supplied by the German manufacturer Reckli and the color pigments of the supplier Remei, a German-based company also. The cement used for the concrete production is provided by Cemex, whereas the aggregates are coming from local suppliers. With the only exception of granite chips which are imported from Sweden owing to a lack of local resources.

In order to meet the quality requirements of the respective target markets the precast concrete elements bear Scandinavian quality seals, apart from the CE marking.

A lot of successful projects

realized at home and abroad

Whether in the British metropolitan city of London, in the Northern German Hanseatic City of Hamburg, in the Danish Egedal, in Sweden’s capital city of Stockholm, at the Lofoten archipelago belonging to Norway, in the domestic city of Riga or many others – the respectable list of references is impressive and includes successfully realized building construction projects: starting from residential and office buildings to schools, hotels, hospitals, TV studios, production and service centers as well as libraries and extending to complete airport buildings.

The question concerning the future prospects is answered by the General Manager, Karlis Roznieks, with a twinkle in his eye: “I would have to lie if we were not expecting to see further growth. Apart from the existing markets and customers, we will expand our activities to further European countries as well as overseas markets in the medium- and long-run”.