Wood-concrete composite construction for increasing sustainability? Analysis of various floor systems

Wood-hybrid construction has enjoyed growing popularity during recent years, especially owing to the increasing focus on low-carbon, sustainable construction with economy of resources use, as practiced by users, investors, project developers and planners.

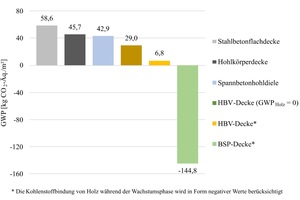

It was planned to perform an assessment of the difference in the quality of the environmental impacts of construction methods, as evidenced by a comparison of a wood-concrete composite floor (WCC floor) with other, partly resource-optimized floor systems. This assessment is derived from the structural requirements to be placed on floor systems on the basis of an actual reference project with the wood-concrete construction method.

The research was made on the basis of several environmental indicators in accordance with DIN EN 15804, including the global warming potential (GWP). The period under review covered the manufacturing phase (Module A1 to A3). The preferred data basis was ÖKOBAUDAT (Version 2021-II) issued by the German Federal Ministry of the Interior, Building and Community, also with partial application of the Environmental Product Declarations (EPDs) outside this database.

Case distinction took place in balancing the GWP of the wood-concrete composite floor. In the first case, consideration took place of CO2 absorption of wood during the growth phase; in the second case, the GWP of wood was set to zero (GWP0). Despite the resulting

significant differences, the wood-concrete composite (WCC) floor demonstrates in both cases a better GWP balance than does the hollow

core prestressed slab, which is the most efficient concrete floor used in this comparison.

Disadvantages of wood result in terms of energy consumption, which relative to 1 m³, lies by a factor of 10 above the requirement of, for example, concrete C25/30.

Overall, it is still necessary to note that, due to significant deviations in the dataset available, no precise statement on the real environmental effects of the systems is possible. Instead, it will be necessary to interpret these effects as qualitative estimates.