What about the cement transition?

For several generations now, Portland cements have constituted the basis for the concrete model of success, a building material which, like no other, characterizes our environment and of which approximately 11 billion m³ have been used up in building last year. Why then should we work with other cements than with conventional Portland cements in the future? Can the future cements not just be that of the past?

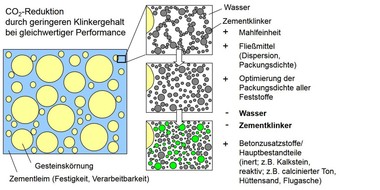

A quite essential reason for a needed cement transition are the substantial CO2 emissions which are associated with the production of classic Portland cement (1 t of Portland cement means approximately 1 t of CO2). In combination with the huge cement consumption this leads to the fact that the production of cement is responsible for about 8 % of the anthropogenic CO2 emissions.

But which substance will substitute the material of which we will need about 6 billion t annually in the future? Certainly not special binders, with raw materials existing not even close to the dimensions needed. The appropriate instrument for reducing the CO2 emissions caused by raw materials in the production of cement will be the substitution of burnt Portland cement clinker by composite materials used in cement in the foreseeable future. Apart from the traditional materials like blast-furnace slag and fly ash, whose usable quantities will decline in the future, there is a need for alternatives. These are primarily calcined clays but also modified steel slags.

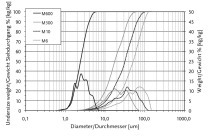

In addition, work on new binder systems with low CO2 emissions is ongoing, these are not based on classic Portland cement clinker. However, many of these alternative binders do not have the potential for a mass-produced building material. Large potential is however provided by alternative, highly reactive belite cements (LTBB) which, at considerably lower calcination temperatures and increased performance, show a much better carbon footprint than Portland cements (Fig.).