Future of Buzzi Unicem cements is CGreen

The future of Buzzi Unicem cements is CGreen. A product line of sustainable cements has been created by know-how and innovation.

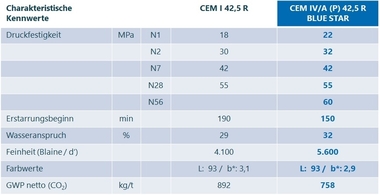

Under the label of CGreen, Buzzi Unicem brings a new product line with CO2 efficient cements to the Italian and German markets. CGreen stands for the natural further development of the hydraulic binders made by Buzzi Unicem, combining the sustainability policy that characterizes the company and the effort to achieve the targets towards an ecological transition. A long tradition of high-quality and high-performance products is continued in this way. The CGreen product line has been developed by selecting suitable active admixtures, replacing clinker to some extent, optimizing grinding and mixing conditions and by using a new generation of additives. At the same time, the required technical performance was kept.

„The ecological transition“, states Antonio Buzzi, Chief Operating Officer Cement Italy, „requires us to adapt our behavior and actions so as to compensate our carbon footprint: We all are responsible for reducing CO2 emissions, which are considered to be a key factor for the amplification of the greenhouse effect and thus the climate change. Therefore, it is a matter of reshaping production processes, distributions systems and consumption structures partially or completely, what in turn ushers in the beginning of a potential industrial revolution and a change in our habits.“

Product line of sustainable cements created

In order to meet this challenge and to include the entire value-added chain into this process, Buzzi Unicem opts for innovation with a series of products duly selected which are able to reduce the ecological footprint. On the basis of the Global Warming Potential (GWP) indicator, that indicates the carbon footprint of each individual binder, the Italian CGreen cements were reclassified and organized so as to highlight those products with the best environmental performance particularly. Besides, like all cements of Buzzi Unicem, the CGreen cements also come with an Environmental Product Declaration (EPD) in accordance with the EPD certification system, which guarantees full transparency and significance of the environmental performance of the product throughout its life cycle.

CGreen will be the trademark that distinguishes all cement types with a low carbon footprint in those countries, where the group is operating. Therefore, the Dyckerhoff Eco Comfort cements and Dyckerhoff Cedur cements already introduced on the German market also bear the CGreen label. Dirk Beese, General Manager of Dyckerhoff GmbH explains: „The CGreen Dyckerhoff Eco Comfort and Cedur cement types are our new cements with a carbon footprint that is up to 39% lower compared to standard Portland cements. These cements are our solution to an increasing demand for CO2 efficient cements in our markets.“ CGreen is an additional step towards achieving the energy transition objectives. The company is pursuing them as well by investing in projects for reducing all emissions and for the development of technologies for capturing and re-using of CO2.