UHPC used in pressed concrete products

Ultra-high performance concrete (UHPC) has special properties, and manufacturers of prefab products expect that it will be used more and more in the years ahead as the applications horizon continues to expand. Machine components made of UHPC already exist. Betonwerk Lintel is the first manufacturer to use UHPC in the production of pressed concrete products.

Betonwerk Lintel produces concrete products which are made of UHPC and are marketed under the Brevolith brand. The company exploits specific properties of UHPC, namely near-zero porosity, high structural density and high strength. The concrete is virtually impermeable to liquids including salt solutions, making it highly durable. UHPC has these properties because the fines have a high packing density. Special plasticizers are used to reduce the amount of water needed.

Less susceptible to

damage by road salt

Betonwerk Lintel produces special Brevolith curbstones which are an enormous improvement in municipal road construction. They are very strong and much less susceptible to damage caused by road salt.

Due to the high proportion of fines and the low water content, UHPC places special demands on the mixing equipment. Numerous trials carried out by university researchers and prefab manufacturers in recent years have shown that Eirich mixing technology has substantial advantages in UHPC processing such as short mixing times (e.g. wet mixing times < 60 seconds), in many cases lower plasticizer consumption, etc.

Mixing pan

transports material

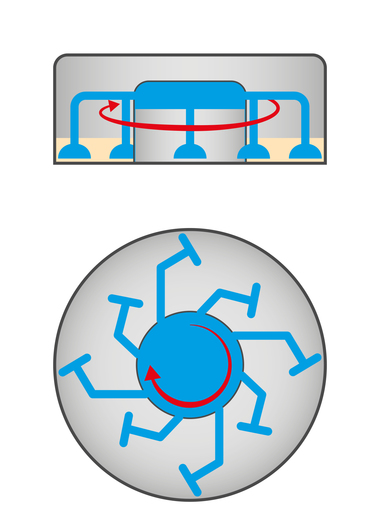

During the UHPC mixing process, every cement particle must be coated with plasticizer. Mixers which generate maximum shear forces in the mixture have distinct benefits. The Eirich mixing system is ideally suited for these applications. The material being mixed is transported by the mixing pan, which means that fewer mixing tools are needed at the bottom. Even at high tool speeds (in the case of UHPC up to 20 m/s), there is no increase in friction and wear.

Betonwerk Lintel has been using Eirich mixers for facing concrete for about 20 years. An RV12W (250 l) was recently delivered for UHPC production. The swivel-head bridge with mixing tool easily swings up and out, providing easy access for cleaning the mixer (Fig. 1).