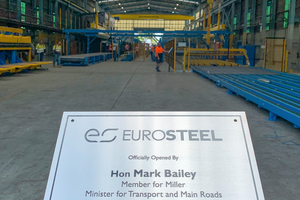

Successful installation of mesh welding plant in Australia during pandemic

Euro Steel was established as the primary supplier of the reinforcing needs to the Euro Precast business by introducing a new mesh welding plant with a bending machine supplied by Progress Maschinen und Automation, a company of the Progress Group. Despite several restrictions and high safety measures, Progress Maschinen und Automation, in close cooperation with the client, managed to set up the plant and provide a full service even during the pandemic.

Australian precast industry reinforced with

automation

Precast has always been a highly recognized construction method within the Australian construction industry. As the cost of labor increases, the construction industry constantly reviews the market for innovation and new technology to minimize onsite labor. For this purpose, the highly automated mesh welding plant was the first choice for Euro Steel. The M-System mesh welding plant allows to produce mesh up to N20 and the integrated bending system BGM allows for fully automated bending of the mesh into complete reinforcement cages. The main feature of the system was the ability to create mesh for precast solid walls through an automated process.

Mr. George Spiropoulos, Director of Euro Precast and Euro Steel, points out the importance for automation in the precast and reinforcement industry in Australia: “The mesh welding plant is a fantastic machine which allows the production of larger bar meshes without the use of labor. The accuracy and quality of the product is something that labor cannot produce alone.”

M-System mesh welding plant

Fully flexible production of tailored mesh containing any combination of lengths, widths, wire diameters and pitches is the key advantage of the M-System mesh welding plant. Consisting of three main components, the MMR straightening unit, the fully flexible welding gantry as well as the BGM wire bending machine, the plant creates a continuous flow of production. Each phase of production is based at a separate workstation, working independently of one another but aligned through customized software.

The MMR straightening system with rotor straightening technology features eight electrically driven rotors each equipped with five staggered straightening dies. The Progress rotor straightening technology ensures constant straightening results and exceptional processing quality of all steel types in compliance with even the most severe standards thanks to the principle of using separate wire feeds per wire diameter. Wire changeover is performed fully automatically within a few seconds, and all wire diameters are permanently clamped into their own rotor available just in time.

The additional BGM wire bending machine, which can work with wire diameters up to 16 mm, is an efficient, flexible bending machine electromechanically operated for the automatic production of three-dimensional mesh such as cages to an exact size. The machine is equipped with a rapid clamping system for the removal of bent mesh.

The welding gantry is carrying out the mesh welding, which is computer-controlled and thus ensures precise welding in combination with efficient energy consumption. Euro Steel benefits from the many advantages of highly flexible mesh production: tailoring mesh to fit static requirements through variable bar placement and diameters; eliminating material waste; eliminating or greatly reducing manpower requirements; reduction of lead times, logistical effort, and storage costs.

The process control system and the Profit management software from Progress Software Development, also a member of the Progress Group, ensure optimal planning, control, and production. It allows for all the production jobs to be planned and monitored remotely. Thanks to the PTS test service unique to progress, every product can be tested in a virtual environment before sending it to the machine. This is particularly valuable with complex products such as customized mesh and cages. In case of an error in the drawing, the software will recognize it and send a warning as well as suggestions for how to eliminate the error. This guarantees that no time is lost during the actual production process. With the Stabos unit, which offers statistical information, the production process can be monitored even more efficiently, and long-term inefficiencies can be effectively eliminated.

The machine software controls the entire production process from the coil to the finished mesh and thus allows for minimal manpower to be used.

Challenging times lead into a bright future

“The overall experience with Progress has been exceptional. From the planning phase through to commissioning, the professionalism of the progress team is amazing. Understanding the large financial investment in such machinery, it is important to know that a company supplies and supports its product in a way that the customer is left satisfied”, says Mr. Spiropoulos and adds: “Progress has done this for me and the business.”

CONTACT

EuroPrecast Pty Ltd

451 Sherwood Road

Sherwood QLD, 4075/Australia

+61 7 3278 2725

progress Maschinen & Automation AG

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979-100

Progress Software Development GmbH

Julius-Durst-Straße 100

39042 Brixen/Italy

+39 0472 979-900