Special shuttering system for funicular railroad

Ratec based in Hockenheim (Germany) is continuously expanding the sales program in respect of special shuttering made to customers specifications. In the last two years, the company developed, designed and made various kinds of customized shuttering. Here, it is always most important to find an efficient solution in close coordination with the customer.

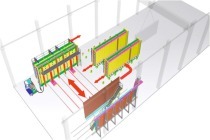

The project „Gleis Typing“/Stärkste Standseilbahn der Welt (world‘s strongest funicular railroad) is regarded as exemplary for a customized solution. The project is realized with protruding reinforcement. Vetsch located in the town of Klosters in Switzerland being in charge with the realization of the project faced Ratec with the following question: How can the elements required for the construction of the funicular railroad be manufactured on tilting tables?

Maximum flexibility

When the engineers of Ratec had examined the drawings of the individual components, they came to the conclusion that the best to do would be to manufacture the elements in formwork especially made for this purpose and thus achieving the maximum flexibility, quality and productivity.

Requirements on the surface of the elements - such as the brush stroke, the track bearings, the installation of dowels as well as various mounting parts as, for example, the roller boxes made of prefabricated glass-fiber reinforced plastic (GFRP) - had to be taken into account in the design and development of the shuttering concept. In fact, considering these requirements considerably influenced the calculation of the precast elements.

A customized shuttering solution allowed using normal concrete as a substitute for the roller boxes due to an integration into the „typing“. Consequently, the costs per concrete element were remarkably reduced.

Optimum surfaces

Another challenge in developing the shuttering concept was the task to work with as little basic shuttering as possible. For this purpose, the production period required was determined using five shuttering tables at which seven different concrete element types can be manufactured.

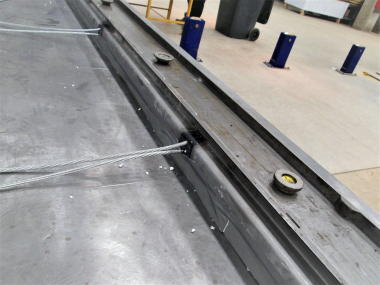

It was decided to manufacture the concrete elements „overhead“ thus ensuring an optimum surface for all visible concrete surfaces. Furthermore, it is possible to concrete the roller boxes in one pour when manufacturing „overhead“.

An especially designed drilling pattern ensures to fix all mounting parts as well as sleeves for dowels exactly and accurately. To achieve a consistent contour of the element‘s upper surface a brush stroke specified by the client was realized by means of a textured formliner.

In developing the shuttering concept, it was ensured that the production of the elements required as few working steps as possible. The shuttering is designed to enable reusing it again as manufacturing table after being used for the „typing“.