Soiling of concrete block pavements

In the past, conventional materials normally used for filling the joints between block pavers and slabs were repeatedly found to cause discolorations of concrete paving products. Similar soiling can also be caused by other foreign materials, such as soil or fertilizers put to interim storage near the paved area. Such effects are often very similar to extensive white bloom, which is why even experts in the field often mix up these two phenomena.

In March 2017, the Neuwied Materials Testing Institute initiated a research project supported by 22 companies and the Betonverband Straße, Landschaft, Garten e. V. (German Concrete Association for Roads, Landscaping, and Garden Construction) by contributing funds, assets and engineering expertise, with the aim of determining the influential factors that trigger the above-mentioned discolorations and agreeing on appropriate corrective actions to reduce the material’s susceptibility to soiling.

The related tests proved that currently used joint-filling materials often lead to marked discolorations of block pavers.

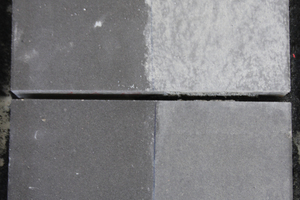

A major portion of block pavers exhibited pronounced discoloration (brightening) of the product surface after application of joint fillers.

The darker the color of the pavers, the stronger their discoloration. Thus, the risk of soiling caused by application of joint-filling materials is considerably lower if pavers in bright or nuanced shades are installed.

No correlation was identified between the paving blocks’ surface texture and their soiling behavior.

Furthermore, it was found that concrete block pavements should be wet-cleaned as early as possible after installation and joint filling (cleaning upon work completion). Dry cleaning is usually insufficient (see Fig.).

If the joint filler remains on the paved surface for a longer period, this will significantly increase the risk of discoloration caused by the applied joint-filling materials. Such staining can be so tenacious that even high-pressure cleaning will not completely remove it.

The tests conducted as part of this research showed that discolorations caused by joint-filling materials migrating into block pavers or onto slab surfaces occurred largely independently of the technical or visual quality of the products.

Product surface staining by joint fillers can primarily be prevented, or at least reduced, by choosing suitable product colors (i.e. pavers in bright or nuanced shades) and joint fillers, as well as by appropriate final cleaning as early as possible after installation. A wet method must be applied for cleaning upon completion. In contrast, dry brooming will usually be insufficient.