Projects with surface-refined precast concrete elements in Spain and France

ANDECE presents below several recent projects where precast concrete elements have helped them meet requirements such as faster construction time. In this article, priority is assigned to projects with surface refinement 2021.

Sustainability is a broad concept that in the case of construction involves addressing numerous aspects, grouped into each of the three dimensions of sustainability: environmental, social and economic. Precast concrete elements are the most technified expression of materializing the main construction material, concrete, as a result of obtaining finished products in the factory and, therefore, subject to the intense controls of an industrial process, to later assemble them on-site, forming all types of constructions.

In this technical article are included some of the most exciting projects in which precast concrete elements with surface refinement have played an essential role in the final result of the work.

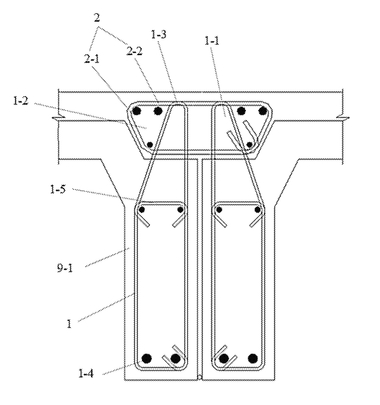

1 Multi-family building with 12 dwellings and parking in Girona, Spain (Fig. 1/2)

This building with a maximum degree of industrialization uses a huge variety of precast concrete elements.

The 17-meter-high columns with a square section of 30x50 cm and another hexagonal section of ø 35 cm incorporate metal brackets hidden inside the inverted T and L-shaped beams and are very small to achieve a minimum slab depth (20+5 cm slab plus 10 cm overhang).

The balconies are made of solid cantilevered slabs, and both the stairs and the communication cores are also precast elements. The concrete structure has been combined with some metal elements for interior mezzanines. The façade panels are 10 cm thick and are made of white concrete, with a textured finish using Graphic Concrete technology.

Prefabricator: Roansa https://www.roansa.cat/projectes.php?idIdiomaCap=2

2 Architectural white concrete elements for a residential building in Granada (Fig. 3/4)

Aedas Homes, one of the leading national development companies, is undertaking the Tarsia residential building, an exclusive development consisting of 212 homes in C/ Hermigua in Granada. Ingennus have carried out the project management - Ferrán Calzada, in collaboration with Gonzalo Arias; the construction management by A2A - José Antonio Fernández; and the construction by Vialterra.

The following precast concrete elements have been used:

Panel in two textures, smooth and striped facade. The white is precast concrete, and the smooth black has been painted with Keim silicate paint.

Balcony and terrace front panel white untreated concrete with striped texture.

Beams, pillars and slatted panels for the pergola at the development entrance.

Benches made of 10 cm thick, smooth white panel.

Prefabricator: Prefabricados Hermanos Quijada http://grupoquijada.com/

3 Public school Les Arts in Valencia (Fig. 5/6)

One of the milestones of the Casal Arena de València project has been the construction of new infrastructures for the Les Arts public school. Its pupils have a new building and location at the beginning of the 21/22 school year. Licampa 1617, the company promoted by Juan Roig to build the Casal España Arena in Valencia, has completed the construction of the new school. The former school facilities will be converted into a public park with green areas that will serve as a walkway between the Arena and a parking lot. More than 400 students are already benefiting from the 20 classrooms of this school, whose design has been carried out by Erre Arquitectura.

Pretersa-Prenavisa has manufactured and placed the following industrialized concrete elements on site: The main structure (pillars, beams and hollow core slabs/pre-slabs), façade enclosures, basement walls, elevator core, stairs, bleachers and partial fencing of the plot, giving value to solutions that are increasingly used in tertiary and residential building: Beams with hardly any sagging and hidden brackets, bilama walls for earth thrust containment, concrete enclosure panels with textured finish, as well as fair-faced concrete.

Prefabricator: Pretersa-Prenavisa https://pretersa.com/

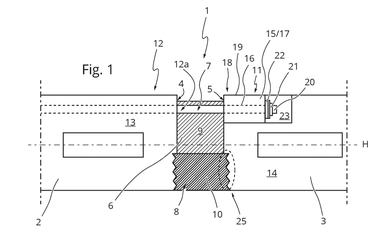

4 Structural panels of the new office building Polaris North Madrid (Fig. 9)

The Fermin Vázquez b720 studio team was in charge of this complex and ambitious project in which Homu Project, Dinmas and Valladares engineering also participated. Built by Sacyr, the project consists of the integral remodeling of the Manoteras 12 building (former Yellow Pages offices) in Madrid for Onix Capital Partners. The work consisted of the complete refurbishment and extension of the building to 7 floors to convert it into a sustainable and efficient office building that aspired to the highest Leed and Well Gold certifications.To this end, the remodeling of the existing 5,310 m2 was undertaken and expanded to 21,200 m2 built with the most avant-garde construction techniques.

In this case the concept of industrialization is included from the design itself, making the most of the advantages of concrete; the panels have a dual function of enclosure and structural element since the post-tensioned slabs of up to 17 meters in span are anchored and supported by the panels, transmitting the load to the large starting beam. In general, there are two types of panels, one design for the north and south elevations with 650 mm ribs orthogonal to the facade and another for the east and west sun lighting with vertical ribs inclined at 37º on opposite sides.

Due to the singularities of the project, the construction process has been designed specifically, and in detail, the lower panel was placed before the execution of each slab to leave part of the front of the slab free to allow post-tensioning tasks. For this reason, the collaboration between the prefabricator‘s technical office, Prehorquisa, the Sacyr team and the project management was constant and essential, resulting in a significant reduction of the construction time, greater quality control and a reduction of on-site waste.

Prefabricator: Prehorquisa https://www.prehorquisa.com/es/

5 Metro Madrid Headquarters (Fig. 7/8)

Building located next to Plaza de Castilla, in Madrid, consisting of structural elements: ribs or pillars and beams precast in gray concrete with black glaze primer over the entire exposed surface, manufactured with HA50/AC/12/IIa concrete dosage. The structural ribs have a trapezoidal section of 20x24x80 cm, with heights between 5 and 6.78 meters.

The hidden connection between ribs has been solved employing embedded sheaths at the head and corrugated waits at the foot, subsequently filled and filled with controlled shrinkage mortar. The connection to the „in situ“ reinforced concrete structure has been made with indirect friction-cut support with corrugated steel waits. Except for a start on the first and second floors, with direct support and fastenings with anchor plates and connection plates.

The roof is made of inclined precast frames, following the façade ribs. They were made with trapezoidal section ribs and beams, similar to the rest of the facade. In this case, the ribs were 15 meters high, and the beams were 18 meters long.

Prefabricator: Indagsa (Grupo Ortiz) https://www.indagsa.com/

6 Project for 40 apartments in Montpellier (France / Fig. 10/11)

There are 5 practically identical buildings, with 8 apartaments per building and 2 floors high, for 3,300 m2 executed.

The Arctic Wall system by Hormipresa has been used in this project, consisting of a 30 cm thick sandwich panel to form the enclosures, combined with 20 cm wide prestressed hollow core slabs that make up the floor slabs. This system allows maximum optimization in the execution of the work.

Prefabricator: Hormipresa https://www.hormipresa.com/vivienda/

CONTACT

ANDECE

Industría Prefabricado Hormigón

C/Diego de León 47

Edificio Melior

28006 Madrid/Spain

+34 913 238 275