Pedax double bending centers put reinforcing steel into perfect shape

Before putting reinforcing steel into use at the construction site, it must be precisely straightened, cut and bent into shape, either from coil or rod, from material up to 50 mm diameter. For processing from coil, Pedax has developed a new especially productive double-bending center. It combines the functionality of a servo-driven stirrup bender with the possibility of producing bent shapes on both ends in only a single workstep. The pneumatic system and the high-performance servo-technology of the double bender are powered by valve islands and cylinders from SMC.

Reinforcing steel is not only “freshly” produced directly at the construction site – it is also used in precast elements. The machines must furthermore be flexible enough to master the different tasks with only one operator and, in this way, to increase productivity. Reinforcing steel from coil material with double bends is increasingly needed, for example, for reinforcing bored piles and in bridge construction. For precise bending of long workpieces on both ends, as well as for manufacture of normal stirrups and bars on only a single machine, Pedax has developed the innovative Twinmaster 16 X + DB NEO double bending center.

A modern reinforcing-steel processing center

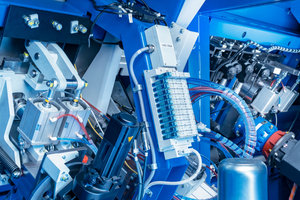

The double bending center from Pedax is one of the company’s latest developments. The machine, first introduced at Bauma 2019, requires only one workstep for producing bent shapes on both ends. “Processing both sides on workpieces of such length is made possible by our completely swiveling workscreen. This enables precise guidance for bending the coil material with very high precision, as well as the use of bending cores. This significantly increases the precision and dimensional accuracy of the end products and leads to considerable increase in productivity. The bending center is at the same time able to produce especially accurately bent, closed stirrups and processes, in addition, double wire up to 15 mm thick,” says Christian Rings, Project Manager at Pedax. The pneumatic system of the double bending center is controlled by a flexible SY valve island from SMC, while cylinders of series C55 and CP96 provide the necessary pressure.

To ensure the especially long service life and high quality of its machines, Pedax carries out all relevant production steps itself – CNC milling, turning, welding, final assembly – in its plant in Bitburg, Germany. A comprehensive after-sales service looks after the machines as soon as they are in operation at the customer’s site.

Controlling compressed air reliably and converting it into contact pressure

For processing in the new double bending center, the wire is pulled from the reel to the bending tool via several feed wheels. The servo technology used here is extremely energy-efficient. The required high contact pressure of the wheels on the wire must be generated pneumatically – for which a precise, high-performance pneumatic system is required. The process is, at the same time, dynamic: “The individual compressed-air consumers must be selectively supplied with high air volumes,” explains Christian Rings. “However, power peaks of this order may not affect the compressed-air system to maintain its stability.” For this reason an effective compressed-air buffer is required. To ensure this, the pneumatics experts at SMC have developed a robust and high-performance package of flexible SY valve islands, C55 and C96P cylinders as well as a maintenance unit from series AC40 with VBAT compressed-air tank.

The compressed air is first generated via the modular maintenance unit and subsequently conducted into the compressed-air tank from series VBAT. The tank, with its charge, smooths the power peaks that occur during operation. “A SY7000-valve island then takes over central control of the pneumatic components,” says Detlef Hett, Team Leader Sales with SMC. “The mounting plate accommodates valves of different sizes, flow-rates and designs. And the exchange functions so smoothly that Pedax customers can do this themselves.” In the energy-saving versions, valve power consumption at only 0.1 W per reel is especially low. The SY valve island with its electric magnetic valves is very robust. It moreover satisfies IP67 and IP40 degree of protection.

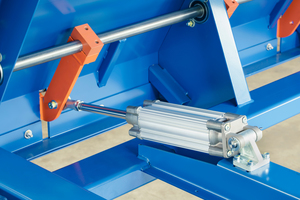

The compressed air, controlled by the SY7000 valve island, is used in several critical places in the 16 X + DB NEO Twinmaster bending center. The feed reels that transport the coil material from the wire magazine through the machine, for example, require high contact pressure. “This is the only way to bend the reinforcing steel quickly to millimeter precision,” explains Detlef Hett. Two parallel-mounted C55 compact cylinders supply the required force, together with the toggle mechanism. Detlef Hett: “Our compact cylinders offer high performance without taking up too much space. They are therefore especially well suited for the new bending center from Pedax.” The components can, moreover, be flexibly attached, fitted with signal transmitters on four sides. They offer, in their most powerful version, lifting forces of up to 5,500 newtons. A safety ring construction enables fast and simple maintenance. Profile cylinders of series CP96 – as well as KQ2 threaded joints and other components such as connectors and hoses – round off the pneumatic package for Pedax.

High-performance pneumatics for a dynamic process

“An optimal power supply is fundamental for smooth operation of our innovative and flexible Twinmaster 16 X + DB NEO bending center,” emphasizes Christian Rings. “Together with the automation specialists at SMC, our engineers were able to develop a number of suitable solutions for our machine.” All components from SMC are designed for long service life and availability – but, if spare parts should be required, a worldwide service and support network will deliver them quickly anywhere.

Text: Markus Leich, Sales Engineer SMC Deutschland