New verification method for flexible support

The judgment issued by the European Court of Justice on 16 October2014 in Case C-100/13 means that, since November 2016, the DIBt has no longer been in a position to grant national technical approvals for prestressed-concrete hollow-core slabs. Approvals that have not yet expired can be used, on a voluntary basis, for verifying compliance with the requirements stipulated in applicable codes and standards. Most of the approvals granted for prestressed-concrete hollow-core slabs will expire at the end of 2019. For the last two years, the German Committee for Structural Concrete (Deutscher Ausschuss für Stahlbeton, DAfStb) has been working on a new guideline designed to ensure the continued safe use of such products in construction works.

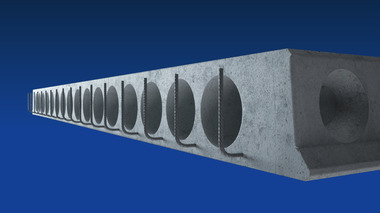

The DAfStb guideline on “Structural Components made from Precast Hollow-Core Slabs – Part 2: Prestressed-Concrete Hollow-Core Slabs” should complement existing codes and standards and provide guidance on how to apply the harmonized European standard DIN EN 1168:2011-12. This guideline includes not only the verification methods known from national technical approvals but also specifications for work execution and requirements for internal and third-party product monitoring and quality control.

For the first time, this guideline contains specifications on how to design and install prestressed-concrete hollow-core slabs in structural systems with flexible support, which can be assumed if the deformation of the supporting beam exceeds 1/2000 of its length under the rare (characteristic) effects acting on the beam-slab composite system after joint sealing. For this case, the guideline includes a generic design method for determining the shear resistance in flexible support. Annex B to the guideline describes a method to determine the cross-sectional parameters for the purpose of designing hollow-core slabs of any cross-section for flexible support conditions.