New type of cleaning plant for hardening grids

WKB Systems, a manufacturer of machines and plants for, among other things, the autoclaved aerated concrete industry, is launching a newly developed cleaning plant for hardening grids.

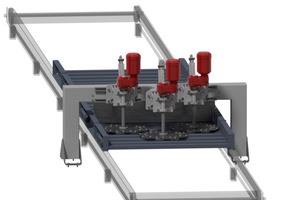

The plant, which the hardening grid passes through by means of a car-feeding system, measures 1,700 mm in length, 2,500 mm in width and 1,600 mm in height. The plant is equipped with three rotary tables driven by one 2.2-kW gear motor each; the speed of each one of the rotary tables is governed via a potentiometer. The rotary tables are fitted with cleaning tools and lowered onto the hardening grid electrically or pneumatically – the first two when the grid has interrupted a first light barrier upon entering the plant; the third rotary table is lowered separately after the grid has interrupted a second light barrier.

Contrary to the cleaning plants of other manufacturers, the rotary tables are not fitted with brushes but with blades – customers can choose between roughing and smoothing blades. According to WKB Systems, the plant is faster because of the different type of tools – it has a cleaning speed of 70 mm/s – and requires less maintenance as the blades wear out more slowly than brushes.